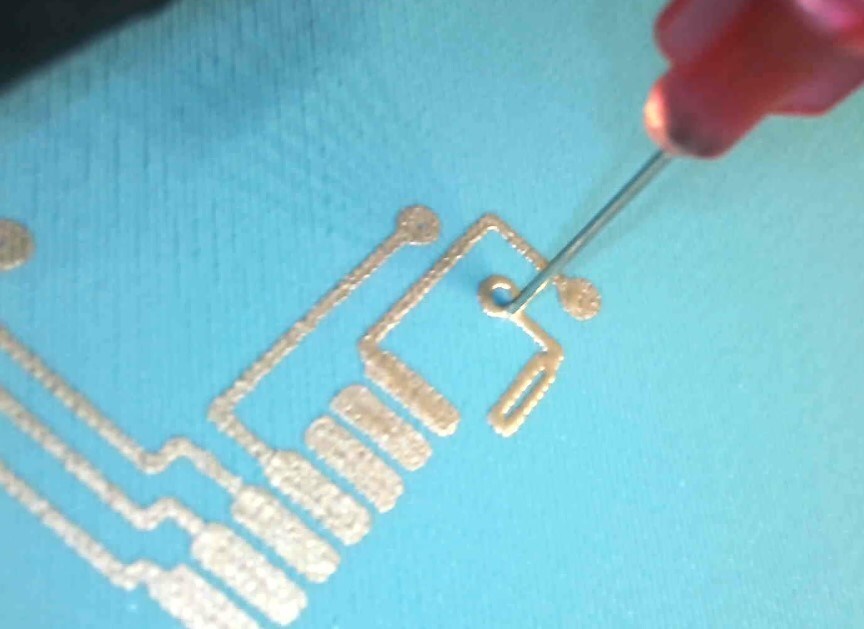

Nano3Dprint’s new DW100-24 silver conductive ink is reported to be well-suited for direct write printing on pre-existing substrates or for embedding into PLA, ABS, or other 3D printed materials. (Photo: nano3Dprint/PRNewswire-PRWeb)

Nano3Dprint developed the inks in partnership with Creative Materials.

BURLINGAME, Calif.—New Conductive Silver Ink Products introduced by Nano3Dprint (stylized as nano3Dprint) for use in the company’s A2200, B3300, and MatDep Pro 3D printers are part of the company’s efforts to “revolutionize the direct-write printed electronics industry,” according to a release from nano3Dprint.

Nano3Dprint, an additive manufacturing and printed electronics technology company, said it developed the inks in partnership with Creative Materials, a specialty chemical products provider headquartered in Ayer, Massachusetts.

Key features of nano3Dprint’s Conductive Silver Ink include high conductivity, precision printing, and versatility. The 3D printers developed by nano3Dprint are designed to print multi-material devices, printed electronics, and specialized applications. They combine Fused Deposition Modeling (FDM) extrusion and a materials dispensing system for functional inks and pastes.

This combined print technology is capable of printing electrical interconnects and other functional materials into the body of 3D printed parts, according to nano3Dprint.

Nano3Dprint DW100-24 is a waterborne, low VOC (volatile organic compound) electrically conductive ink and coating. It is suitable for application by direct-write 3D printing using nano3Dprint’s line of multi-material 3D printers, the company said in the release.

DW100-24 can air-dry at room temperature or be heat cured at 100°C – 175°C for maximum conductivity. The product offers adhesion to Kapton, Mylar, glass, PLA, ABS, and a variety of other surfaces. Unlike conventional conductive materials, it is reportedly “very resistant to flexing and creasing,” the release stated.

Applications for DW100-24 include are reported to include embedded 3D circuitry, medical electrodes, printed circuit boards (PCBs), polymer thick film circuitry, membrane switches, and static elimination. DW100-24 is N-methyl Pyrrolidone free, according to nano3Dprint.

“We’re excited to collaborate with Creative Materials to bring these cutting-edge conductive silver ink products to the market,” said Ramsey Stevens, CEO of nano3Dprint, in the release. “Our commitment to innovation and sustainability drives us forward.”

According to nano3Dprint, the exceptional electrical conductivity of the silver ink formulations make them suitable for “a wide range of applications, from flexible circuits to sensors.” The nano3Dprint technology is said to ensure precise deposition, allowing engineers and designers to create intricate patterns with ease. Whether users are working with rigid substrates or flexible materials, DW100-24 conductive silver ink adheres uniformly, enabling smooth integration into various electronic devices.

Applications for the inks are reported to include printed electronics, wearable technology, the internet of things (IoT), and medical devices.

Nano3Dprint’s conductive silver inks enable the fabrication of printed circuit boards, antennas, and touch sensors. Designers can incorporate conductive traces directly onto flexible substrates and fabrics for wearable devices. The inks facilitate the creation of smart sensors, RFID tags, and other IoT components. They are also compatible with embedded electronics applications, making them well-suited for next-generation orthopedics and embedded sensor medical devices, the company said.