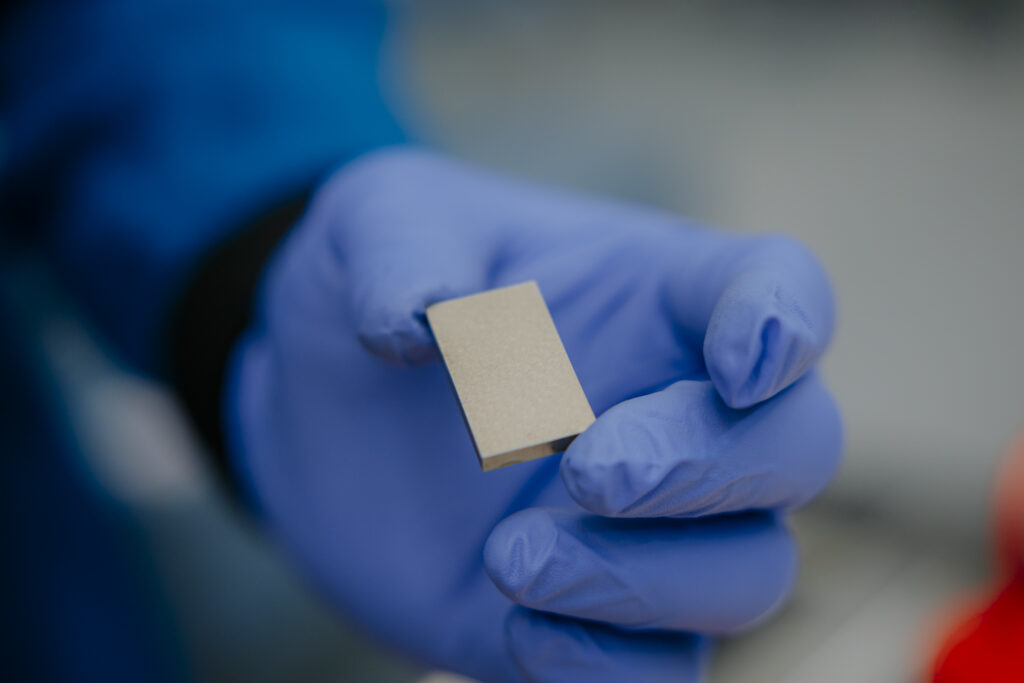

A rare earth magnet is inspected at MP Materials’ Independence facility in Fort Worth, Texas. (Photo: Business Wire)

Trial production of automotive-grade, sintered NdFeB magnets is underway, with first deliveries on track for year-end, the company said.

FORT WORTH, Texas—In January, MP Materials reported that its flagship Independence facility in Fort Worth began commercial production of neodymium-praseodymium (NdPr) metal, as well as trial production of automotive-grade, sintered neodymium-iron-boron (NdFeB) magnets.

The achievements are said to bring the U.S. closer to re-establishing a fully integrated, domestic supply chain for these critical components for the first time in decades. In a company release, MP Materials said it had “reached a pivotal milestone in restoring the U.S. rare earth magnet supply chain.”

“This milestone marks a major step forward in restoring a fully integrated rare earth magnet supply chain in the United States,” said James Litinsky, founder, chairman, and CEO of MP Materials, in the release. “With record-setting upstream and midstream production at Mountain Pass and both metal and magnet production underway at Independence, we have reached a significant turning point for MP and U.S. competitiveness in a vital sector.”

A front view of Independence, MP Materials’ state-of-the-art rare earth magnet manufacturing facility in Fort Worth, Texas. (Photo: Business Wire)

NdFeB magnets—the world’s most powerful and efficient permanent magnets—are essential components in vehicles, drones, robotics, electronics, and aerospace and defense systems. Despite their indispensable role, the U.S. has relied almost entirely on foreign sources for these critical inputs for decades.

MP Materials is addressing this gap by building America’s first fully integrated rare earth metal, alloy, and magnet manufacturing facility. With commercial NdPr metal production already online and trial production of sintered magnets underway, Independence is poised to produce approximately 1,000 metric tons of finished NdFeB magnets per year, with a gradual production ramp beginning in late 2025, the company said.

The facility will supply magnets to General Motors and other manufacturers, sourcing its raw materials from Mountain Pass, MP Materials’ mine and processing facility in California.

In 2024, MP Materials reportedly achieved record-breaking production at Mountain Pass, delivering more than 45,000 metric tons of rare earth oxides (REO) contained in concentrate. The company called it “an all-time high for U.S. primary production.” Mountain Pass, America’s only active rare earth mining and processing operation of scale, is also reported to have set a midstream production record, producing approximately 1,300 metric tons of NdPr oxide in 2024, in addition to cerium, lanthanum, and other separated and refined products.

MP Materials produces specialty materials that are vital inputs for electrification and other advanced technologies. The company said it is “currently expanding its manufacturing operations downstream to provide a full supply chain solution from materials to magnetics.”