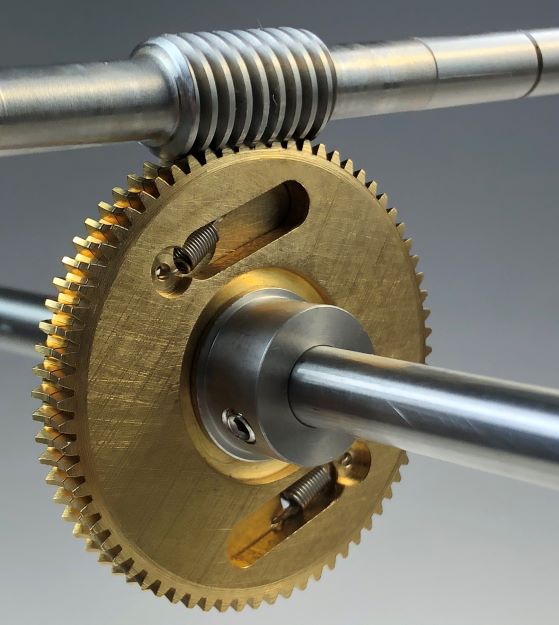

This photo illustrates how a worm wheel and worm shaft work together. (Photo courtesy Nordex)

BROOKFIELD, Conn.—Over the last several decades, a Connecticut-based company has made a name for itself as a manufacturer of mechanical and electro-mechanical parts and sub-assemblies for the medical industry and other high-growth markets.

Following its incorporation in 1960, Nordex, Inc., focused on designing and manufacturing surface mount technology assembly equipment in its early years. In the 1970s, the company modified its product line as it began producing miniature, precision electro-mechanical parts and assemblies, according to its website.

Today, Nordex operates as a highly engaged design and manufacturing partner capable of providing custom components and fully integrated, turnkey subsystems. According to Dan Agius, Jr., a mechanical engineer who serves as the company’s chief financial officer, engineering expertise is one of the keys—along with a companywide commitment to quality and continuous improvement—to Nordex’s growth through the years.

“Our engineers work with our customers to optimize their design for performance, manufacturability, and cost-savings,” Agius said in an emailed response to Design-2-Part. “If any customer is having trouble designing a product or designing a product that can actually be manufactured in a cost-effective manner, we have a team of engineers ready to assist them.”

Nordex employs about 55 people at its 25,000-square-foot facility in Brookfield, Connecticut, where its focus on quality has earned the company certifications to the ISO 9001:2015 and AS9100D quality management system standards. In addition to these certifications, Agius said that Nordex is ITAR registered and DFARS 252-204-7012 compliant.

“Our employees are top-notch, and their commitment to our customers keeps our customers coming back to Nordex to buy additional parts and assemblies,” Agius added.

Dan Agius, Jr., took time out recently to provide written responses to Design-2-Part’s questions about Nordex’s unique capabilities as a manufacturer, and what keeps its customers coming back for more. Following are his responses, lightly edited for length.

A worm and worm shafts, custom manufactured by Nordex. (Photo courtesy Nordex)

Design-2-Part: What industry sectors does Nordex serve?

Dan Agius, Jr.: Our top industry is the medical industry. We also have significant presence in the laboratory diagnostic, robotics, defense, aerospace, industrial automation, and semiconductor industries. Our clients are predominantly OEMs in those industries.

D2P: What design, engineering, or manufacturing services does your company provide in support of these industries?

DA: Nordex is a manufacturer of power transmission components and sub-assemblies. We have a large catalog of standard components, but approximately 75 percent of our business comes from custom parts and assemblies, with a focus on gear manufacturing.

Ten percent of our employees have engineering degrees, and we work with our customers to optimize their designs for manufacturability and cost. With some customers, we have worked to completely redesign their products for significant functionality improvements and cost savings. Our engineers are gear and mechanical power transmission experts who are eager to help our customers!

D2P: What types of parts does your company produce for OEMs and product manufacturers in these sectors?

DA: Our bread and butter is gear manufacturing: gears (spur gears, helical gears, and straight bevel gears), racks, pulleys, worms, and worm wheels. We offer a wide range of sizes: We can manufacture gears from 2mm in outside diameter up to 500mm in outside diameter (about 20 inches).

We also manufacture and distribute the components that utilize the gear—the shafting, housing, bearings, bushings, fasteners, et cetera. A significant portion of our business then takes these disparate components and assembles them into a single, turnkey sub-assembly.

In the sub-assembly business, we have the capabilities to act as a customer’s CM (contract manufacturer) for that sub-assembly. We will source parts as required from the customer-specified suppliers for items like motors and bearings, purchase them ourselves, and install them into our customers’ complete sub-assemblies. This saves our customers the effort of dealing with multiple vendors for their parts; instead, they can buy fewer parts.

In the medical industry, our products are used in hospitals all over the world. While you won’t see any Nordex-branded machines, there’s a very good chance that Nordex parts and sub-assemblies are inside diagnostic and/or surgical machines in any hospital you may go to.

D2P: As a supplier/partner to OEMs/product manufacturers, what is your company’s biggest strength? Why do customers choose your parts or services?

DA: Our company’s biggest strength is our commitment to quality. We are ISO 9001:2015 and AS9100D certified. We have been ISO certified since 1996. Our commitment to quality permeates our entire company. Every employee at Nordex and the Nordex management team is committed to going above and beyond to exceed our customers’ expectations and meet their requirements, even if that means working late nights and on weekends.

Our employees are top-notch, and their commitment to our customers keeps our customers coming back to Nordex to buy additional parts and assemblies.

We have several longstanding relationships with large customers that go back decades. With that type of relationship, our account managers and engineers understand the needs of the customer. These relationships would not exist but for the excellence of our employees and our company’s commitment to quality.

D2P: In what ways do the company’s personnel apply advanced skills or expertise in manufacturing parts or providing manufacturing services for your customers?

DA: Gear manufacturing and design is a specialized field. Chances are that most of our customers’ engineers did not even take a class on gears when they were in college.

We have decades of gear manufacturing and design experience and are eager to use that experience to aid our customers. We back this up with cutting edge gear manufacturing machinery—this enables us to provide our customers products as efficiently as possible, and to the highest quality possible.

D2P: Depending on the process used, what are some examples of tolerances or other quantifiable results that your company can achieve with your manufacturing processes?

DA: We produce gears up to the quality of a DIN 3 (AGMA Q14). For features such as outside diameters, we routinely make parts and tooling to a tolerance of 0.0002 inch.

Pulleys and custom shafts crafted by Nordex. (Photo courtesy Nordex)

D2P: Have you had any recent expansions to your facility or additions to its production capacity?

DA: Nordex is committed to continual improvement, and a tangible area where we show that commitment is through adopting newer CNC machinery, particularly for gear and rack manufacturing. This CNC machinery increases our capacity and throughput.

D2P: Can you describe, without disclosing proprietary information, an application that illustrates your company’s ability to solve a technical challenge?

DA: Nordex worked with our customer to develop a gear train used in medical diagnostic equipment. It combined spur and bevel gears for a miniature application with little-to-no backlash and the ability to provide a high amount of indexing accuracy.

D2P: What was the major technical/engineering challenge?

DA: The major challenge was developing a bevel set with the smallest possible pitch to fit within the working space available. The smallest gear on the drive train could be no larger than 0.125-inch in OD.

An additional challenge was effectively interfacing the bevel gears with the spur gear drive train so it would provide minimal to zero backlash.

D2P: How did the company apply its services to meet the application requirements?

DA: We created gear designs based on our customer’s technical requirements. Nordex engineers made suggestions on the material and design utilized in the gears to improve the overall performance and minimize the cost of the customer’s application.

Our engineers used CAD software and CNC gear machines to design and manufacture prototypes. They needed to rely on their years of experience and work closely with our customer to validate the prototypes and develop production parts. The Nordex assembly department then took the various components and assembled them into a single turnkey unit.

Manufacturing processes included turning, milling, gear hobbing, gear shaping, and assembly.