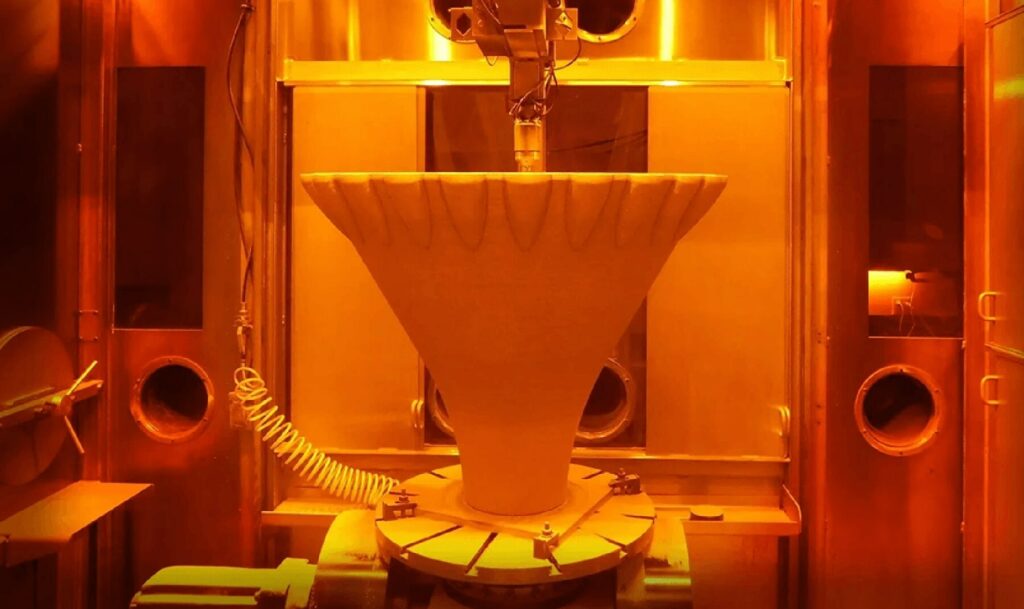

Manufacturing a large-scale aerospike demonstration nozzle with integral channels at the RPM Innovation (RPMI) facility in Rapid City, S.D. (Image: Elementum 3D/PRNewswire-PRWeb)

Elementum 3D and RPM Innovations, Inc. collaborated with NASA on the project, said to enable aerospace engineers ‘to see the nozzle as proof-of-concept that informs new component designs.’

The following article is an edited version of a release from Elementum 3D.

ERIE, Colo.—Elementum 3D reported that it collaborated with RPM Innovations, Inc. (RPMI) as part of NASA’s RAMFIRE (Reactive Additive Manufacturing for the Fourth Industrial Revolution) project to design, print, and successfully test a new additively manufactured rocket nozzle made from Elementum 3D’s A6061-RAM2 aluminum powder. The achievement “advances ongoing efforts to exceed current rocket performance and efficiency,” Elementum 3D said in a release.

Elementum 3D, a specialist in materials and process development, creates advanced metal alloys and metal ceramic composites. RPM Innovations, Inc., “specializes in manufacturing and repair techniques using Directed Energy Deposition (DED),” the company’s website stated.

At the Marshall Space Flight Center last fall, NASA performed a successful hot-fire test of an additively manufactured aluminum rocket nozzle—a feat that some had thought to be impossible, according to the release.

The goal of the NASA-funded Reactive Additive Manufacturing for the Fourth Industrial Revolution (RAMFIRE) project was to transition rocket engine technology to a laser powder-directed energy deposition (LP-DED) process to enable large-scale production. The prior approach used lightweight, additively manufactured aluminum alloys printed with a laser-powder bed fusion (L-PBF) process capable of experiencing huge temperature gradients up to 6000°F, the release said.

This breakthrough is said to support efforts to make large-scale nozzles, including aerospikes, available to industry.

The RAMFIRE project printed a large-scale LP-DED aerospike demonstration nozzle with integral channels made of Elementum 3D’s A6061-RAM2. This result “allows aerospace/space engineers to see the nozzle as proof-of-concept that informs new component designs,” Elementum 3D said in the release.

For nearly seven decades, rocket engineers have sought an alternate design to the standard bell-nozzle rocket engine. The aerospike design breaks free from the traditional design, which is efficient at only one point in the rocket’s trajectory, the company said.

Why is this innovative nozzle a sought-after option, especially since the bell nozzle is a proven design with adequate capabilities throughout the history of human spaceflight?

According to Elementum 3D, the aerospike’s inside-out rocket nozzle plume travels externally, rather than exiting from within a traditional bell-shaped nozzle. The main advantage is that, as the rocket climbs, atmospheric and airstream pressure keep the plume at optimum conditions along the entire trajectory. This allows highly efficient engine performance, including better performance over a range of pressures and altitudes, delivering higher payloads while decreasing overall rocket weight, the company said.

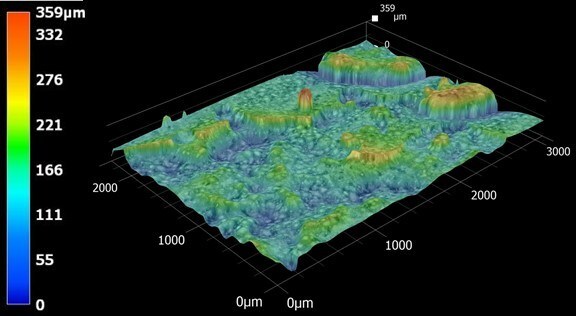

A segment of the as-printed aerospike rocket nozzle surface, before smoothing by REM Surface Engineering’s Extreme ISF process. (Image: Elementum 3D/PRNewswire-PRWeb)

If rocket launches are more efficient using the aerospike nozzle design, why has it never been seriously tested on the launchpad?

According to Elementum 3D, the lack of actual flight test data has precluded the use of these nozzles in current and next-generation space launch vehicles. Moreover, the aerospike nozzle configuration presents unique design and fabrication challenges. These and other factors have meant limited test opportunities and a dearth of actual flight test data, precluding use of the aerospike design on current and next generation launch vehicles, the company said.

Additive manufacturing has changed perspectives about the ability to test and implement the aerospike design in a cost-effective manner.

NASA recently validated data from hot-fire tests on its 3D printed Rotating Detonation Rocket Engine (RDRE), which is not a traditional combustion engine. It reported that recent advancements in 3D printing can overcome some of the engine’s design challenges—specifically, how to manage its temperature. The ability to print the aerospike demonstration nozzle with a qualified high-strength, lightweight aluminum alloy is a significant step toward developing a larger version, the release said.

NASA commissioned Elementum 3D to work closely with its RAMFIRE project engineers and scientists and RPM Innovations, Inc., to develop and print a 36-inch-diameter aluminum aerospike rocket demonstration nozzle out of Elementum 3D’s A6061-RAM2 material. RPM Innovations performed the build with its large-format LP-DED process.

Directed energy deposition (DED) uses a focused energy source to create 3D printed parts with powder or wire feedstock. With DED, metal deposition and fusion occur simultaneously. A nozzle deposits material into the focused beam of a high-power laser under tightly controlled atmospheric conditions. The feedstock melts and deposits as the tool path progresses, according to the release.

REM Surface Engineering supported the RAMFIRE project’s post-production with its Extreme ISF Process. Its team uniformly removed approximately 400 µm (400 microns) of surface material from the aerospike nozzle surface, which reduced surface roughness/waviness and hot-wall thickness. The benefits of improving the hot wall surface texture are reported to include extending the nozzle’s fatigue life and creating a more uniform surface for heat transfer/heat pickup properties.

The wall thickness reduction can reportedly bring DED parts into final geometric tolerances. Although not performed on this unit, internal channel finishing for rocket nozzles and similar components can reduce particle shedding and pressure drop caused by as-printed roughness.

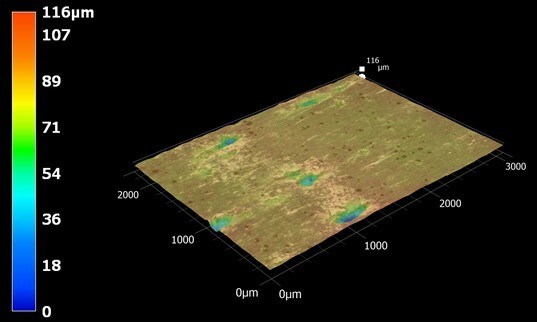

The RAMFIRE Aerospike Nozzle, made of A6061-RAM2 and printed via a DED-LPB process, is shown after hot wall polishing via REM Surface Engineering’s Extreme ISF® Process. Surface roughness of the hot wall was reduced from Ra of ~57 µm to ~0.4 µm. (Image: Elementum 3D/PRNewswire-PRWeb)

Why has it taken almost 70 years to successfully produce a lightweight, high-strength aluminum rocket engine?

For one thing, the design requires conformal cooling channels to flow cryogenic propellants that keep the nozzle well below the material’s melting temperature. Internal channels are an additive manufacturing specialty and are far too complex to create with traditional machining processes.

Second, metal additive manufacturing via laser melting processes only became industrialized in the past few decades as computer, automation, and laser technology grew more sophisticated and affordable.

Finally, the ability to additively manufacture aerospace-grade aluminum has only become possible in the past decade. Elementum 3D said that since 2014, it has gained extensive knowledge and experience developing “impossible-to-print” high-strength aluminum feedstock powders with its patented Reactive Additive Manufacturing (RAM) technology.

Standard aluminum alloys are highly prone to a type of cracking, called hot tearing, under the rapid heating and cooling conditions inherent to laser welding processes. Industry considers popular wrought aluminum alloys, including AA6061, unweldable for this reason. Elementum 3D’s RAM chemistry is reported to control the solidification process, producing crack-free, fine-grained microstructures and printed material with strength equal to—and, in some cases, superior to—wrought aluminum.

Will the combination of A6061-RAM2’s optimized thermal and mechanical properties, coupled with the design freedom of additive manufacturing, be the path to designing and manufacturing new, innovative rocket engines that rival the efficiency of an aerospike rocket engine?

The RAMFIRE Aerospike Nozzle, made of A6061-RAM2 and printed via a DED-LPB process, is shown after hot wall polishing via REM Surface Engineering’s Extreme ISF® Process. Surface roughness of the hot wall was reduced from Ra of ~57 µm to ~0.4 µm. (Image: Elementum 3D/PRNewswire-PRWeb)

Only time and further research can answer that question. “The research data acquired from optimizing A6061-RAM2 aluminum alloy for large blown-powder DED improves engineers’ confidence in the ability to improve rocket efficiency to meet or exceed the aerospike’s performance,” Elementum 3D said in the release.

Elementum 3D specializes in materials and process development, as well as creating advanced metal alloys and metal ceramic composites. The company developed and patented its reactive additive manufacturing (RAM) materials technology, enabling high-performance materials printing that reportedly had not been previously possible. One of the company’s strengths, according to Elementum 3D, is its ability to develop custom materials tailored for specific applications.