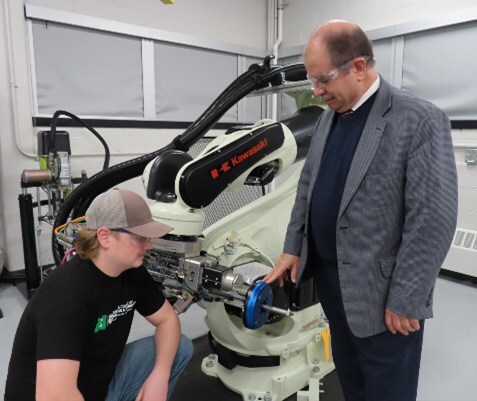

Associate Professor Emad Tanbour works with Tyler Werth, a mechanical engineering student, in the Coherix 3D computer-vision and virtual-reality lab at Eastern Michigan University in Ypsilanti. (Image: Coherix/PRNewswire)

More than 70 mechanical engineering students are expected to participate over the next three years in a program focusing on the growing field of adhesive-dispensing technology.

YPSILANTI, Mich.— Coherix, creator of 3D-enabled adaptive-process-control systems for application of adhesives, said in a release that it is working with Eastern Michigan University (EMU) in Ypsilanti to develop “factory-of-the-future” manufacturing and assembly technology.

The three-year program at EMU’s GameAbove College of Engineering and Technology is focused on precision-manufacturing applications in the growing field of adhesive-dispensing technology. It is supported by a $385,000 grant from Coherix, the company said.

GameAbove Dean Mohamad Qatu said that an important objective of the project will be to help expand the use of computer vision, virtual reality, and adaptive-process-control systems in the automotive, medical, and consumer-electronics industries.

“The program will provide our students with experience in the programming and use of industrial robots to dispense adhesives and sealants in the manufacture of cars, medical devices, and consumer electronics—technology that could save billions of dollars in manufacturing costs,” Qatu said in the release.

Coherix, headquartered in Ann Arbor, Michigan, is a pioneer in the development of 3D-enabled adaptive-process-control technology. The company provides high-performance adhesive-dispensing inspection technology to global OEMs, tier-one suppliers, line builders, dispensing-equipment companies, and vision-system integrators in a variety of industries.

“We are looking forward to partnering with Eastern Michigan University,” said Coherix Chairman and CEO Dwight Carlson, in the release. “Our goal is to offer engineering students at the university advanced factory-of-the-future training, as well as access to the latest adaptive-process-control and dispensing-system technology under development at Coherix.”

Over the next three years, more than 70 mechanical-engineering graduate and undergraduate students are expected to take part in the program developed and directed by Associate Professor Emad Tanbour. A major part of their work will take place in a computer-vision and virtual-reality research facility at EMU provided by Coherix, the company said in the release.

According to Tanbour, all of the undergraduate students currently enrolled in the Coherix program are Michigan residents with an interest in pursuing engineering careers at companies with facilities in the state.

Several other companies provided equipment for the Coherix laboratory. Kawasaki Robotics, for example, donated an industrial robot, Sames supplied dispensing equipment, and the Gonzalez Group provided safety fencing, according to the release.

“I feel as though I am getting a real engineering experience, thanks to Coherix and Professor Tanbour,” said Tyler Werth, an EMU mechanical-engineering senior from Milan, Michigan, in the release. “Through the Coherix program, I’m finally able to get the co-op internship experience that I have wanted. I also have been able to work on my senior project with some of the best dispensing engineers in the nation.

“I’m learning technology I didn’t even know existed. I have programmed a robot to do things I didn’t know were possible,” Werth added. “This course of studies will open a lot of doors for me and has been the absolute highlight of my four years at Eastern Michigan University.”

According to Coherix, its post-Covid sales have increased at an annual rate of 35 percent and are expected to continue at a similar pace over the next five years. The company reported that

nearly 150 of the world’s leading automakers and tier-one automotive suppliers are Coherix customers. More than 4,000 dispensing systems equipped with Coherix 3D computer-vision technology are reportedly installed on manufacturing and assembly lines around the world.