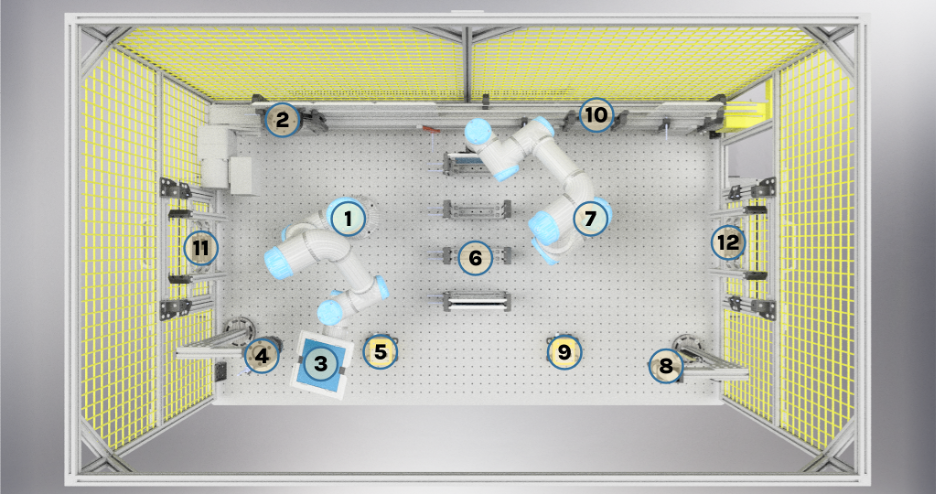

The simplified process flow path starts when the robotic arm (1) takes a workpiece (3) from the conveyor belt pick-up (2) and moves it to the drawing station (4). There the arm will move the workpiece to draw one of the predefined ‘product’ images. It will then position the workpiece for inspection at camera (5) before placing it in the shuttle bay (6). From here, the second robot arm (7) will transfer it to the cleaning station (8) to have the workpiece wiped of all markings and inspected by camera (9). On a passed inspection the now clean plate is placed back at the end queue of the conveyor belt drop-off (10) and the process begins again. (Image courtesy NIST)

American manufacturing is associated with high-quality standards, meant to ensure both the reliability and longevity of the products produced. Manufacturers across all industries are looking for technological solutions and enhancements to continue to meet these high-bar standards and to maintain their competitive advantage. The growing connectivity of devices, coupled with high demands of production and precision, mandate robust monitoring and control systems.

As the digital age blossoms, it’s no surprise to anyone that a full suite of ever-evolving technologies is rising up to provide manufacturers with options for new sensing devices, cybersecurity enhancements, adaptive control, and evaluation systems—all backed by industrial artificial intelligence (AI). As these technologies develop, how can manufacturers determine the best products for their applications, and how do developers find the high-fidelity data needed to test and evaluate their products?

Show me the data!

Access to high-quality, real-world data streams becomes paramount when developing and testing industrial AI technologies or any novel industrial system. Where some companies are turning in-house or to consultants to provide bespoke solutions, many manufacturers simply do not have the time or resources to invest in these options.

This is why the National Institute of Standards and Technology (NIST) has constructed the Collaborative Robotic Operations Workcell (CROW). This benchtop process manufacturing setup represents a collaboration within the Smart Connected Systems Division of the NIST Communications Technology Laboratory. We made this setup to provide an open-access source of data analogous to live industry work without the concerns of intellectual property (IP) or proprietary information that often limits the availability of true industry data.

Where many setups are designed to focus on a single asset or data stream with a specific concern, CROW has been developed to have maximum application potential with a robust suite of sensors and digital loggers. To develop and test solutions that work outside of the laboratory, we need to evaluate their impacts not only on specific assets but across the entire system. This includes digital communications, control systems, product quality, embedded and secondary sensors, material flow, and more. This effort is part of a developing suite of efforts in this area at NIST.

One key aspect of an industrial system that often gets overlooked in similar benchtop setups is the interactivity with and input from the human operators. CROW is specifically designed to facilitate data capture of interactions between any controlling or observing agent—be they human, computer, or some combination of both.

What is CROW?

CROW is a multistage manufacturing operation with the goal of producing and evaluating an endlessly cyclic product stream. In our setup, two robotic arms work together to move glass workpieces through marking and erasing stages in a process that is very similar to industrial gasket extrusion or welding.

We use a marker on glass as a non-destructive, fully recoverable operation that has clear and understandable expectations, requirements, and inspection points. Additionally, this process will allow for a fully autonomous “lights-out factory” style operation should we want to explore such systems.

The setup consists of 10 major physical components marked in the figure below:

* UR3es (1,7): An industrial collaborative robot designed by Universal Robots. Rated for a maximum payload of three kilograms.

* Conveyor belt (2,10): A mini belt conveyor for moving the shuttles from the end of the process back to the beginning. Fitted with a rotary potentiometer that measures the belt speed.

* Station 1: Marking station (4): Fitted with a linear potentiometer for measuring the vertical displacement of the tool.

* Station 2: Cleaning station (8): A motorized eraser for cleaning the workpiece surface.

* COGNEX In-Sight 7000 Cameras (5,9): These are used to produce production quality inspection data for each workpiece.

* Shuttle Bay (6): Holding slots for shuttles between the beginning and end of the manufacturing process. Fitted with photoelectric sensors that detect if a shuttle is present.

* Inspection Doors (11,12): Periodically or on demand, the robotic arms can place individual workpieces in these holders so they may be safely removed and inspected by personnel.

Equipment monitoring may not be easy, but process monitoring is hard

One of the major challenges facing any connected system is the compounding dependencies or cascading effects that are inherent in processes with multiple stages. In manufacturing, it is possible for each phase of a process to be within allowable specifications, but the end result could still be unacceptable if all the in-tolerance processes have minor errors that compound. If a single process misaligns a part by 0.05 inch, that is an acceptable deviation. If that same error occurs 10 times and the part is now half an inch off, that could be an unacceptable final product.

Although this is a simplistic example, there are many cases where similar compounding or cascading errors can cause a big problem in one area when the source of that problem is much further up the line and/or doesn’t trigger any individual out-of-spec alarms. It is only by observing and evaluating the system as a whole that such situations can be detected and nominally avoided. This is one of the major goals of the CROW setup.

Nice—but how can this help me?

Developing standards and best practices are among the most reliable methods for improving long-term productivity, efficiency, and reliability in nearly any system. Couple these with human-centric AI-enhanced technologies, and the outlook for potential gains is magnified enormously.

However, that outlook must also be tempered with an exploration of risks, fail safes, and safeguards against anomalous or unexpected behavior. In short, alongside new technologies, we must also develop the mechanisms that enable trust and ensure trustworthiness. That cannot be done without extensive live testing.

Setups such as CROW provide comprehensive, safe environments to design, deploy, and develop these emerging technologies. Data streams and system enhancements can be added and evaluated onto a benchtop setup like CROW without fear of losing time or endangering resources in a full-scale production facility. Examples include the following:

* Monitoring systems for physical asset performance and reliability

* Cyber information and network traffic security

* Product quality assessments

* Human interactions, feedback, and training

The philosophy of “try before you buy” is very much needed by many facilities. Access to guiding documents and data from these styles of research facilities can provide the assurance and confidence that they are investing their limited resources where they will give the most return.

The experiments performed on CROW will enable developers to test and benchmark their products, allow consumers to better understand the effects of products, compare solutions, and highlight pain points. These efforts also help to develop best practice guides and standard operating procedures to manage, maintain, and sustain intelligent automation now and into the future.

Select areas that will be specifically targeted soon include the following:

* Manufacturing data exchange standards implementation

* Cybersecurity monitoring

* Digital twin or digital surrogate simulations, testing, and control

* Reliability, prognostics, and health management

* Product quality monitoring

* System-level evaluations and impacts

* Human interactivity and feedback through language processing

* Trust and trustworthiness requirements gathering

Further outlook impacts include robot and cobot control enhancements; advanced material handling; data exchange standardization and implementation; digital thread mapping, tracking, and utilization; and more.

But wait—there’s more!

The Industrial Artificial Intelligence Management and Metrology (IAIMM) team led by Michael Sharp, Ph.D., at NIST has a mission to provide evaluation guides and metrics to give apples to apples comparisons and assessments of all levels of intelligent automation. We have created simulators and physical setups to help consumers and industry perform valuable interrogations of products and technologies that could be applied to their setups in a way that is accessible, intuitive, and useful to all relevant stakeholders.

CROW is part of a series of related efforts at NIST to better understand and manage manufacturing processes. The NIST Engineering Laboratory has established a Digital Twin Lab, which includes robot arms for material/part pick and place; a desktop computer numerical control (CNC) machine for cutting parts; a high-precision coordinate measuring machine (CMM) for acquiring high-quality tolerance compliance information; and Quicken Interchange Format (QIF) style documentation, representing a short product lifecycle. It is used to support the research and development on manufacturing digital twins and testing relevant standards. You can learn more about this effort by contacting Matt Triebe at NIST.

As we embrace the era of advanced manufacturing, CROW stands as a beacon of innovation, offering an experimental and data playground for the development and testing of cutting-edge industrial AI technologies. In the pursuit of excellence, CROW not only provides a glimpse into the future of intelligent automation but also fosters a culture of collaboration, standardization, and trust.

As we navigate the intricate landscape of manufacturing, let us push boundaries, explore possibilities, and shape a future where precision, reliability, and human-centric advancements converge seamlessly. Together, let’s build a legacy of excellence that transcends industries and propels us into a realm of unparalleled productivity, efficiency, and sustainable progress. If you have any interest in collaborating, please contact Michael Sharp in the Smart Connected Systems Division at NIST.

Any mention of commercial products within NIST web pages is for information only; it does not imply recommendation or endorsement by NIST.

About the Author

Michael Sharp leads the Industrial Artificial Management and Metrology Project in NIST’s Communications Technology Laboratory. He currently researches methods and metrology to integrate and qualify artificial intelligence for practical use in industrial and manufacturing settings. He received his Ph.D. in nuclear engineering from the University of Tennessee in 2012 and has been an active participant in state-of-the-art research communities for data modeling, sensing capabilities, and artificial intelligence.

Reprinted with permission of NIST.

Source: