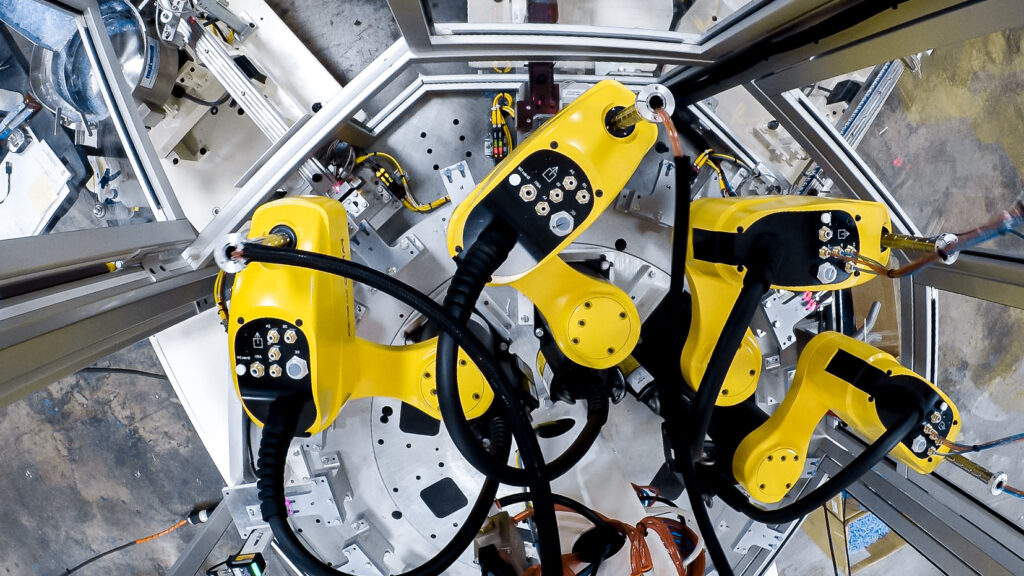

An overhead view of robotic automation. (Image courtesy Wauseon Machine and Manufacturing)

A detailed breakdown of the advantages that can be gained by leveraging automation

The following article was contributed by Wauseon Machine and Manufacturing.

Consumers are demanding: They want quality and speed at the right price, and they expect the manufacturing world to deliver. As organizations everywhere try to meet evolving consumer requirements—all while managing safety, efficiency, and logistics within their facilities—each one faces the looming threat of competitors closing in. With so much on the line, manufacturers are challenged to adopt smart approaches that keep their businesses both profitable and competitive.

More and more, these approaches are being influenced by the prospect of game-changing automation. By integrating smart automation solutions, manufacturers can achieve the kind of operational outcomes that lead to sustainable bottom-line success. In fact, sales of industrial automation equipment, including fixed and flexible options, are on the rise—an upward trend that’s expected to continue as innovation, advancement, and the entire industry landscape mold to the needs of the market.

Fixed Versus Flexible Automation

Fixed automation, sometimes called hard automation, refers to an automated production process with a “fixed” sequence of operations determined by the equipment’s configuration. Essentially, commands are programmed into the machine to operate its cams, gears, wiring, and other hardware that is not easily changed over from one product style to another. Fixed automation enables high production rates and is suitable for large-volume products of identical specs. Examples include pneumatic (air-driven) devices, hydraulic machines, electric cylinder assemblies, cartesian pick and place robots, and parts feeding equipment. These options can be leveraged as standalone automation or in tandem with industrial robots.

Flexible automation, also known as robotics, provides the opportunity to accommodate changes and repurpose automation solutions for fluctuating needs. Industrial robots can be programmed to perform multiple functions for products of varying sizes and materials. Because reprogramming the equipment in flexible automation is performed at a computer terminal (not on the production equipment itself), there is no need to group identical products into batches. A mixture of different products can be produced one right after another. Common applications include welding, material handling and machine tending, as well as picking, packing, and palletizing.

For manufacturers considering whether new or additional automation might fit into their current operations, it’s essential to understand how this investment can positively impact the business. Here, we break down seven of the most compelling ways that leveraging automation can maximize manufacturers’ competitiveness in the industry.

- Manufacturing Automation Reduces Labor Costs

According to the U.S. Department of Labor’s Bureau of Labor Statistics (BLS), unit labor costs (the total labor costs required to produce a unit of output) rose in the vast majority of manufacturing industries in 2019. Of the 51 industries in durable manufacturing, 45 experienced rising unit labor costs. Of the 35 industries in nondurable manufacturing, 32 recorded rising unit labor costs.

For so many companies, labor is the predominant cost in manufacturing a product, not to mention the most difficult one to manage. The most obvious way that automation helps slash this expense is by requiring fewer workers to produce the same number of manufactured goods. Fewer workers means less monetary allocation for not only payroll, but also employee taxes, healthcare benefits, insurance, and other related overhead costs. Of course, this is just one aspect of a much larger labor cost benefit.

Take the high cost of employee acquisition and turnover. For one thing, worker shortages are a real and present challenge in some areas. Recent findings from the BLS Job Openings and Labor Turnover Survey show that the number and rate of total U.S. job openings have increased to 6.6 million (+617,000) and 4.5 percent, respectively. There is also the vastly increasing number of Baby Boomers (born between 1946 and 1964) approaching retirement age. In less than 10 years, all of the workers in this generation will be 65 years or older.

At an estimated 73 million, this generation is one of the largest living age groups, second only to millennials—a population highly unlikely to gravitate toward production roles in manufacturing facilities.

What does this all mean? Well, particularly for jobs that are demanding, dirty, dangerous, or downright unpleasant, the time and expense it takes to fill open manufacturing positions amid current employment conditions can become a major burden—one that automation plays an immense role in easing.

Finally, there’s the cost of absenteeism, which results in a lack of consistency and predictability in terms of planning for production shifts. When workers unexpectedly leave early or call out, it can cause significant and costly disruption to production uptime.

- Manufacturing Automation Maximizes Capacity Utilization

The capacity utilization rate is an important operational metric for manufacturing companies, as it assesses their current operating efficiency. Automation supports higher rates of capacity utilization by fostering greater, faster output without requiring additional per-unit expense.

For instance, if you automate an existing process that was relying on human workers for operation, now you have the ability to produce through lunches and breaks, and even in the event of employee sickness or no-shows. In fact, you could potentially run two 10-hour shifts via the automated process and achieve the same output as you might over a 24-hour period consisting of three 8-hour shifts (given, of course, that each person will require at least one hour of non-production time for lunch and breaks).

Automation works tirelessly around the clock. It doesn’t get sick, get distracted, require vacation time, or take breaks. It is reliable and consistent.

And if demand necessitates a ramping up of your production output without increasing your production time, automation gives you the opportunity to produce more quickly—minus the need to invest in additional production equipment or workers.

- Manufacturing Automation Improves Quality and Accuracy

Manufacturing automation streamlines repetitive tasks and minimizes margins of error. Adoption of modern systems has become critical for maximizing Cpk and alleviating manufacturers’ quality, consistency, and waste issues, manifesting the following outcomes for those who embrace smart solutions.

Repeatability and Precision

Especially in the life sciences arena, such as pharmaceutical and healthcare manufacturing, human error is a big concern. It is essential for these products to have zero defects because people’s health and lives are at stake. With the support of automated solutions that make ultimate repeatability and precision a reality, you can mitigate the risk to both consumers and the organization at large.

Product Safety and Viability

Particularly in the food and beverage industry, production and handling processes that rely on human workers carry increased risk of introducing contamination into the environment, which ultimately endangers the final product. Automated systems minimize human interaction with the product, thereby lessening the potential for contamination by germs, pathogens, or foreign objects that can result in discarded food, complex recall processes, loss of consumer trust, and legal liability.

Reduced Waste

When it comes to applications that involve uniformity and quality, human error has the potential to cause substantial monetary losses. Consider, for instance, companies in the faucet industry that utilize workers to fulfill the polishing process. Because humans, by nature, are prone to making mistakes, a certain number of products will bear defective surface finishes and must be discarded. Automation eliminates this waste.

Mollified Material Damage

In industries where expensive materials and equipment are handled by humans, there’s ample opportunity for error to result in costly damage. Fiber optic cable, as an example, is extremely fragile and, if mishandled by a worker, can cost thousands of dollars. There’s also the risk of humans dropping heavy parts, a mistake that can cause damage to the part itself or to expensive production equipment, or even a workplace injury.

Unrivaled Skill and Consistency

Think about the consistent motion required for production processes like painting and welding. Automation affords a level of technique and uniformity that humans are simply incapable of matching.

- Manufacturing Automation Supports Safety and Ergonomics

According to the U.S. Department of Labor’s Occupational Safety and Health Administration (OSHA), work-related musculoskeletal disorders (MSDs) are among the most frequently reported causes of lost or restricted work time. Musculoskeletal disorders affect the muscles, nerves, blood vessels, ligaments, and tendons.

Workers in many different industries and occupations can be exposed to risk factors at work, such as lifting heavy items, bending, reaching overhead, pushing and pulling heavy loads, working in awkward body postures, and performing the same or similar tasks repetitively. Exposure to these known risk factors for MSDs increases a worker’s risk of injury.

In production facilities lacking automation, workers may be subjected to safety and ergonomic concerns, such as physical stress, strain, overexertion, repetitive motion, awkward postures, and heavy lifting. These can cause employees to experience intractable pain, an inability to work, or physical conditions that necessitate medical care and time off—all of which result in production downtime and higher costs for the organization. On the other hand, automated solutions improve workplace safety while optimizing workflow processes.

By creating a more favorable and ergonomic working environment, automation has the potential to retain talent and limit liability. Safer, less rough conditions, like those cultivated by replacing certain human-performed tasks with machine-operated ones, minimize the risk of seeing a revolving door of workers, the challenge of constantly training new people, the ongoing need to attract employees for hazardous and undesirable jobs, and the liability inherent in unsafe surroundings.

- Manufacturing Automation Accommodates Social Distancing and Fulfillment Demands

In the midst of a global pandemic, with its rippling social and economic impacts, the market for manufacturing automation and industrial robots has exploded. FANUC, the largest maker of industrial robots in the world, has seen its volume demands flourish.

Why is this the case? One big reason is the now critical need for manufacturers to safely space out their workers and limit human interaction. Anywhere people are working in small, confined, or heavily populated spaces, there’s increased risk for exposure to a contagious virus. And just one positive test result can lead to production declines or even a complete shutdown. Manufacturing automation solutions support a reduction in the labor needed to occupy these spaces, thereby mitigating the overall risk of infection.

In addition, there’s automation’s capacity to meet rising fulfillment demands. Especially with regard to product categories that have skyrocketed in response to the onset of stay-at-home guidelines and other pandemic-related nuances, production requirements have amped up for some manufacturers. Automation provides the platform for meeting increased demands and tightened turnaround times.

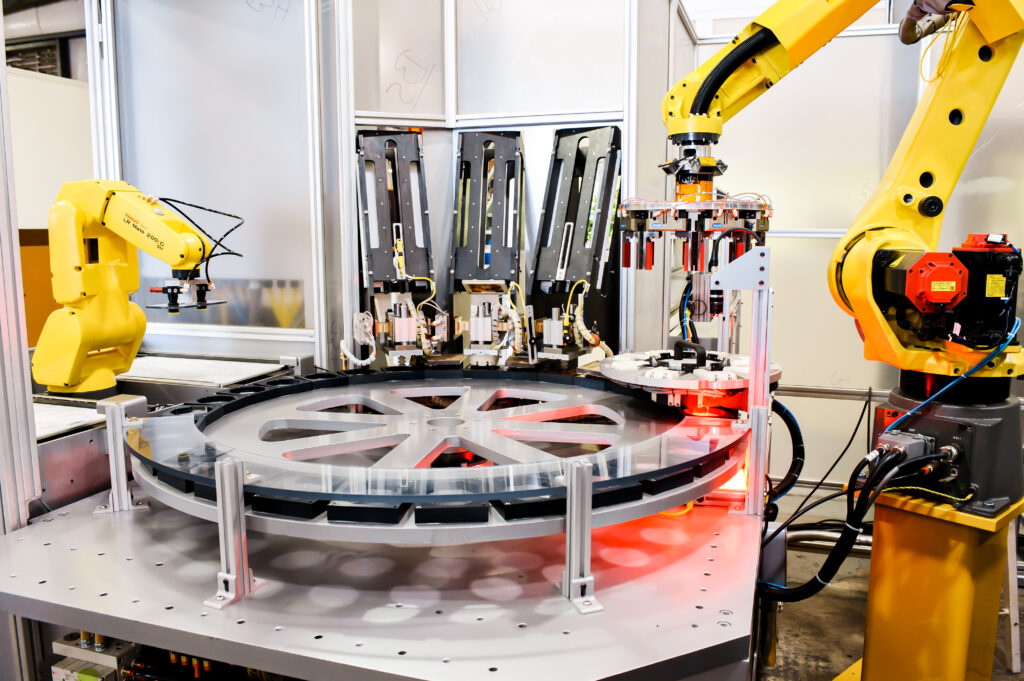

A robotic work cell employing a FANUC LR Mate 200 iC robot. (Image courtesy Wauseon Machine and Manufacturing)

The Role of Robotics Technology in This Era of Dynamic Innovation

According to a release from the Association for Advancing Automation, formerly the Robotic Industries Association (RIA), robots are already deployed across numerous segments of the supply chain, and the industry expects to see an explosion in the number of robots working in warehouses and DCs as the growth of e-commerce fulfillment continues to rise. Even before the global pandemic and coinciding shifts in consumer behavior, decreasing population, and increasing demand, the implementation of robotics and automation was expected to expand as companies look for ways to remain productive and competitive, RIA said in its release, “The Rise of Autonomous Mobile Robots.”

The release went on to say that autonomous robots were once considered a futuristic trend, but are quickly becoming a useful and reliable technology for the logistics industry. Autonomous mobile robots (AMRs) are proving to be a disruptive robotics technology that can increase efficiencies, provide significant cost savings, and mitigate risks associated with human resources. A variety of AMRs are currently in use. Some are considered “collaborative”—that is, designed to work with and around people—while others are considered “non-collaborative,” according to the release. Additionally, this technology is working in structured and non-structured environments, making the implementation more advantageous across several industries.

- Manufacturing Automation Creates Jobs and Minimizes Reliance on Global Outsourcing

There’s a changing perception of automation occurring among the general public. The common judgement, particularly after the last recession, used to be that automation takes jobs away from the American workforce. Now, we’re starting to see a shift in that mindset.

Yes, automation definitely replaces some of the unskilled labor force. By leveraging it to keep factories up and running, however, you’re also sustaining valuable jobs like administrative, human resources, and cleaning and maintenance, not to mention the skilled workers required to program and manage all of the new technology. In essence, manufacturing automation has the potential to create both vast opportunities for employment and a greater reliance on our own domestic resources.

Remember, the U.S. still has the cheapest and most consistent energy supply. And the consumer is here. It’s always cheaper to manufacture closer to your consumer. Manufacturing your product locally, where it is purchased, gives you a huge competitive advantage in supply chain management. Automation enables manufacturers to keep production onshore, giving U.S. companies a competitive edge in the global market.

- Manufacturing Automation Boosts Overall Profitability

The evolution of manufacturing automation has transformed once difficult, slow, and hazardous production tasks into remarkably safer and more productive ones. As automation in manufacturing continues to advance in sophistication, so do the advantages of leveraging such opportunities in facilities across the industry. Although the prospect of adopting a modernized approach to routine operations can seem daunting, the profitability payoffs are well worth the leap.

Given all of the factors mentioned already, it stands to reason that automation can produce and get items to your customers more efficiently, thereby increasing your profit margins— gains that are poised to continue well into the future.

Here’s a more specific breakdown of how some of the previously highlighted competitive advantages amount to cost savings and expanded profitability:

Labor Reduction

With the right automation solution(s), your organization will require less labor for its operations, including reduced human resources (HR) and overhead costs.

Machine Utilization

Production numbers tend to drop as workers become tired or call out, whereas automation has the ability to maintain consistency throughout any shift, from beginning to end. This means your line is set to run more efficiently and without the need to replace equipment as frequently.

Quality Improvements

With the precision of an automated process, you’re positioned to produce less scrap or waste, an important measure of cost savings.

Ergonomic Savings

Automation minimizes the costly risk of workplace injury, including time off, workers’ compensation, increased insurance premiums, and potential compliance fines.

Worker Retention

When automation performs the unfavorable types of tasks once assigned to human workers, it can foster a more amenable work environment. Happier employees generally equate to less turnover, which leads to a more lucrative bottom line.

Designing an Automation Solution For Your Manufacturing Needs

Given the wide span and nature of ways to derive value from automation, it can be argued that just about any manufacturing operation has the potential to glean a competitive edge from embracing it. And even though automation was too expensive for smaller companies to implement some 15 to 20 years ago, this has completely changed over time. Now, automation is suited to organizations of all sizes. As long as you’re seeking to lower cost and improve efficiency, automation is worth your consideration.

The way in which your company ultimately chooses to leverage automation should depend largely on your business goals and operational requirements. Regardless, the opportunities for organizational competitiveness are immense.

Consider partnering with an integrator who will work to understand and accommodate your goals before designing an automation system that fully supports them. Whether you already have detailed specifications for a project or you’re looking for an expert to develop a plan based on your cycle times, product information, and overall business objectives, an experienced integrator has the knowledge and expertise to make your integration a successful one.

About Wauseon Machine and Manufacturing

Wauseon Machine and Manufacturing and its sister company, McAlister Design & Automation, are established providers of robotics automation, tube fabrication equipment, and build-to-print precision machines parts.

Wauseon Machine has four separate focus plants dedicated to tube-forming technologies, robotic automation, and precision machining. Across its plants, the company focuses on tool development, machine building, automation, and providing contract CNC production machining of volume and custom precision piece parts and components for other companies.

Wauseon Machine and McAlister Design & Automation are suppliers of system integration services to incorporate automation into a variety of industries, applications, and innovative technologies for manufacturing.