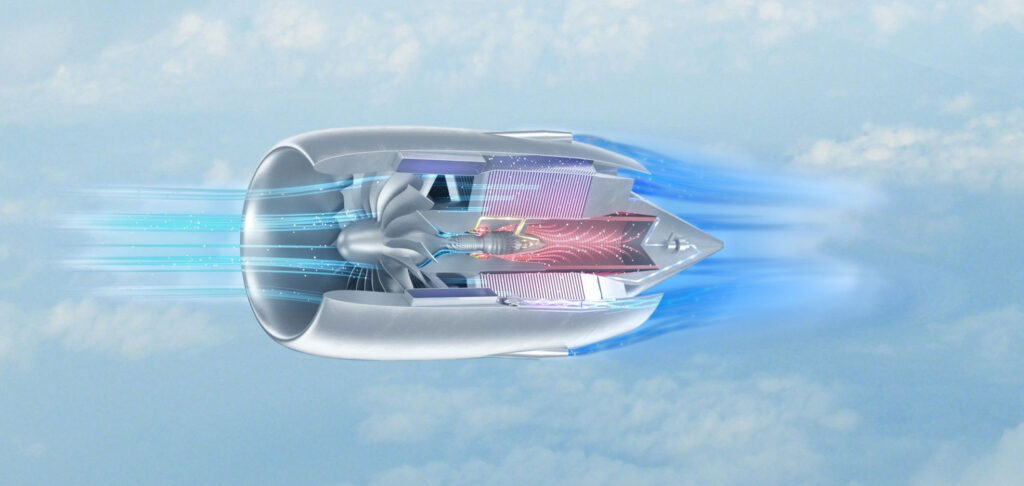

MTU Aero Engines chose GT-SUITE for thermal management simulation of key components of its Water-Enhanced Turbofan. (Image: Business Wire/MTU Aero Engines/Gamma Technologies)

Aero Engines will leverage Gamma Technologies’ software for its novel Water-Enhanced Turbofan

WESTMONT, Ill—Multi-physics simulation software developer Gamma Technologies (GT) reported that a major aircraft engine manufacturer has chosen its software as a tool for thermodynamic simulation of components. The company said in a release that MTU Aero Engines (MTU) selected its GT-SUITE multi-physics CAE simulation software as a tool for thermodynamic simulation of key components for its Water-Enhanced Turbofan (WET), which reduces contrails and CO2 and NOx emissions.

Dedicated to its vision of emissions-free aviation, MTU’s team is “active in the research, development, and manufacture of innovative engine technologies that will help ensure an emissions-free future for aircraft of all power categories,” the company’s website states.

By 2035, when powered by sustainable aviation fuel (SAF) or hydrogen, a WET based engine could reduce the climate impact of an aircraft by about 80 percent compared to a gas turbine engine from the year 2000—making it virtually climate neutral, according to the release.

The WET propulsion concept uses residual heat from exhaust to achieve a steam generator to vaporize water, which is then injected into the combustor. The water for this is extracted from the exhaust gas by means of a condenser and then separated; GT-SUITE helps to simulate the complex heat exchanges from this operation, the release said.

“We are committed to pioneering technology with the goal of sustainable aviation,” said Jochen Gier, Ph.D., team lead of cooling, heat transfer, and combustion at MTU, in the release. “After looking at all the available tools, Gamma Technologies’ GT-SUITE was a perfect fit for our complex WET heat exchanger simulations.”

Dimple Shah, president and CEO of Gamma Technologies, commented on GT’s opportunity to work with MTU.

“Working with visionary organizations like MTU Aero Engines, that push the envelope of engineering to reduce the climate impact and energy use of aviation propulsion, is gratifying and aligned with our corporate mission toward a more sustainable world,” Shah said in the release. “Their commitment to engineering tomorrow’s engines today is admirable, and we are pleased our tools are proving to be instrumental in the development of these amazing technologies.”

According to Gamma Technologies, GT-SUITE includes a complete library of physics-based modeling templates covering fluid flow, thermal systems, mechanics, electrics, magnetics, chemistry, and controls. It supports the entire development cycle, from concept to validation.

Gier added that MTU was “very happy” with the way it can “leverage parametric studies and optimization, user friendly post-processing and the ability to combine 3DCFD results in GT-SUITE to calculate unevenly distributed flows through these components. GT-SUITE fits quite well into our development toolchain and gives us the opportunity to evaluate each component as part of the complete system.”

Applications of GT-SUITE are reported to include a wide variety of engineering systems, such as conventional and hybrid vehicles, powertrains, engines, motors, compressors, catalysts, acoustics, cooling, thermal management, HVAC, hydraulics, lubrication, and multi-body mechanics.