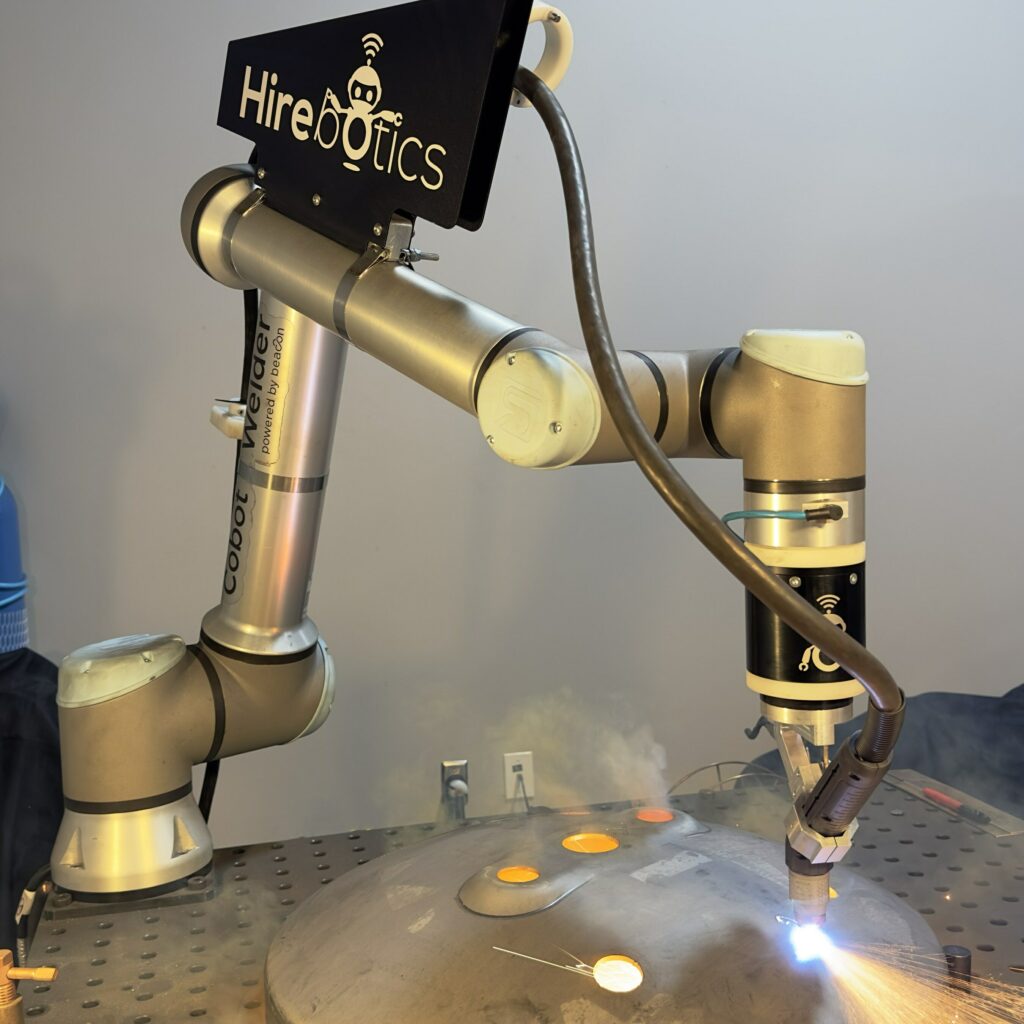

Hirebotics’ Cobot Welder in action. (Photo courtesy Hirebotics/PRNewswire)

Hirebotics has also introduced a new plasma cutter and software tool that uses AI to recommend welding and cutting parameters.

NASHVILLE, Tenn.—Collaborative robotic welding and cutting systems and a cloud-based tool that uses artificial intelligence (AI) to recommend welding and cutting parameters are among the new products and capabilities recently introduced by Hirebotics, a provider of collaborative robots (cobots) for manufacturing.

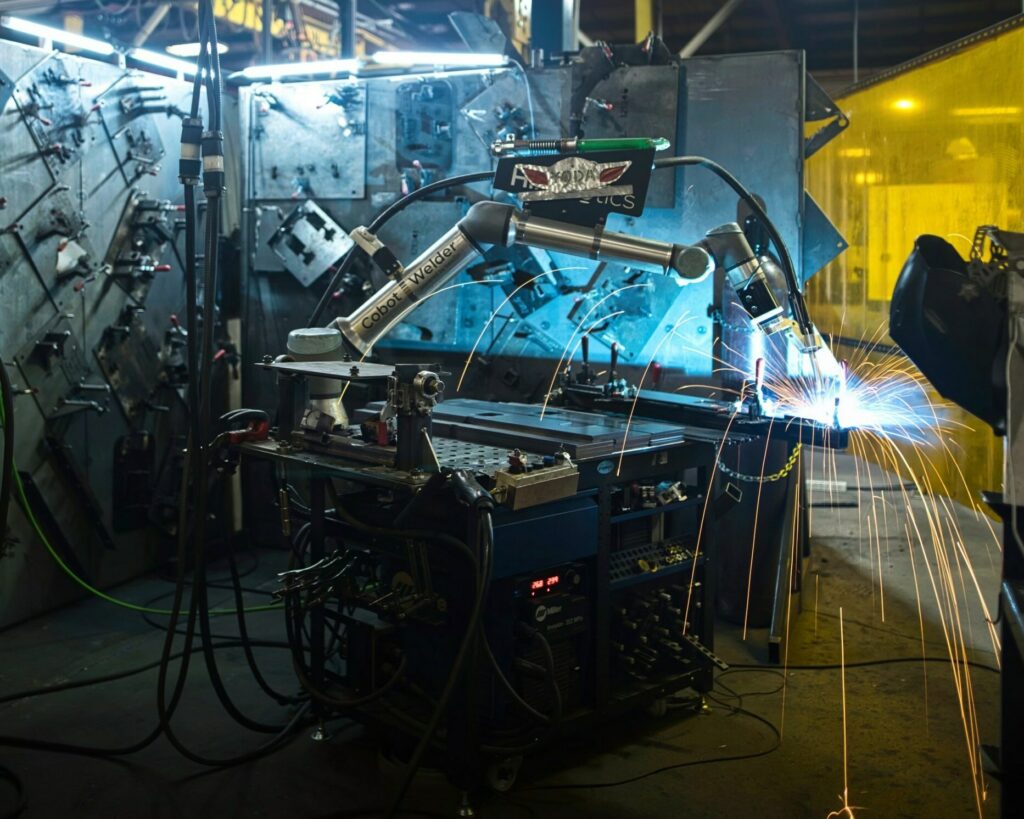

As D2P went into production, Hirebotics was scheduled to roll out its new Cobot Welder and its Cobot Cutter at the FABTECH trade show in Chicago. The Cobot Welder uses the UR20 cobot from Universal Robots to increase reach and handle larger parts that previously required multiple set ups. The Cobot Cutter is a new plasma cutting product that “leverages the ease of use of the Beacon platform,” Hirebotics said in a release.

The company was also preparing to introduce its cloud-based software tool, Beacon Recommendations, which leverages AI to recommend welding and cutting parameters when setting up a part; and BeaconCare, an uptime service for Cobot Welder and Cobot Cutter.

Hirebotics’ Cobot Welder in action. (Photo courtesy Hirebotics/PRNewswire)

BeaconCare includes discounted repairs and loaner equipment if a customer’s cobot, welder, or plasma cutter needs to go in for repair. Hirebotics said it is also offering a flexible rental program that gives customers the ability to try a system before committing to a purchase, or to flex their production by adding Cobot Welders to meet seasonal needs.

“We are excited to unveil our new products and capabilities at FABTECH,” said Rob Goldiez, CEO of Hirebotics, in the release. “We are proud to offer the most advanced and user-friendly robotic welding and cutting solutions on the market. These game-changing tools and flexible solutions will enable our customers to more quickly and easily integrate our cobot welders to their manufacturing facilities.”

The Cobot Welder has been updated to use the new UR20 cobot, a larger cobot with a reach of 1.75 meters that makes it suitable for welding larger parts. The UR10e version of the Cobot Welder remains available for customers with smaller parts or space constraints, the company said in the release.

The Cobot Cutter uses plasma cutting technology and cutting software built on the Beacon platform. Plasma cutting is known as a fast and precise cutting method that can be used to cut a variety of materials, including steel, stainless steel, and aluminum.

The new Cobot Welder, Cobot Cutter, BeaconCare, and rental program will be available immediately following FABTECH. Beacon Recommendations is being released to new and existing customers over the coming months.

Hirebotics’ robotic welding and cutting systems, software, and services are used by manufacturers in industries such as agriculture, automotive, and general fabrication. Hirebotics was named Universal Robots’ top OEM award winner for 2023, the company said in the release.