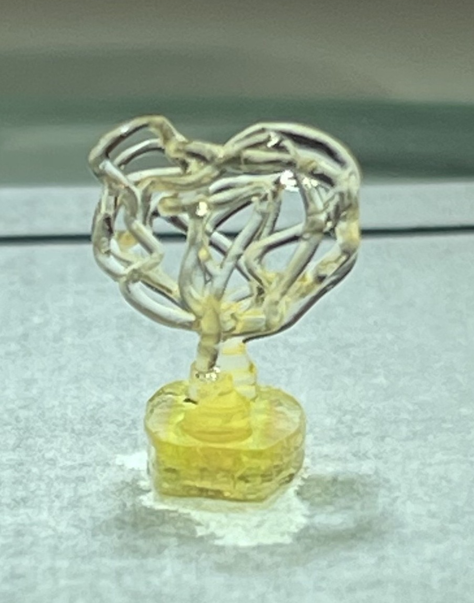

Auxilium Biotechnologies 3D bio-printed perfusable vasculature aboard the ISS, demonstrating the ability to print blood vessels. (Photo: Business Wire)

The achievement by Auxilium Biotechnologies, reported to be a historic first, is said to highlight the potential of space-based bioprinting to create advanced medical solutions for Earth and future space missions.

SAN DIEGO—Auxilium Biotechnologies, a company active in regenerative medicine and bioprinting, reported that it successfully deployed its 3D bioprinter aboard the International Space Station (ISS). The cutting-edge platform, described as the first of its kind, made history by printing eight implantable medical devices simultaneously in just two hours, the company said in a release.

Auxilium Biotechnologies is a pioneering biotechnology company dedicated to developing innovative solutions for treating traumatic injuries to the nervous system. With its focus on innovation and collaboration, the company works to develop cutting-edge bioprinting technology and implantable medical devices to improve lives worldwide.

The Auxilium Microfabrication Platform (AMP-1) harnesses the unique properties of microgravity to create medical devices with what the company called “unmatched precision and efficiency.”

“Microgravity provides advantages for bioprinting, including uniform material distribution and the ability to create finer, more intricate structures that would collapse under Earth’s gravity,” the release stated. “These benefits are critical for implants that incorporate biological materials or therapeutic agents, delivering consistency and reliability that Earth-based manufacturing struggles to achieve.”

The AMP-1 bioprinting system remains on the ISS, using lightweight cartridges preloaded with biological materials to print implants that are returned to Earth. It requires less than a minute of astronaut time per print session, minimizing costly labor valued at up to $130,000 per hour. The system’s lightweight cartridges are said to ensure cost-effective and sustainable transportation via commercial resupply missions.

Auxilium Biotechnologies 3D bio-printed eight implantable medical devices for repairing nerve damage aboard the ISS. (Photo: Business Wire)

“The deployment of our bioprinter on the ISS is a landmark achievement for space biomanufacturing and Auxilium,” said Auxilium Biotechnologies CEO Jacob Koffler, Ph.D., MBA, in the release. “AMP-1 is the most advanced 3D-printing platform ever sent to space, enabling us to develop regenerative medicine treatments that can transform patient care. This facility not only demonstrates the feasibility of mass 3D-printing production in space but also highlights the economic potential of space-based manufacturing. Bioprinting in microgravity will drive innovation benefiting life on Earth, aboard commercial space stations in Low Earth Orbit, and in future space exploration, including upcoming Moon missions.”

AMP-1’s initial applications focus on producing implants for peripheral nerve repair. Future milestones await, including preclinical animal testing and commercialization. In the near term, the implants will be used on Earth, while longer-term applications aim to support space exploration, including missions to the Moon, Mars, and beyond. The ability to bioprint implants in space could significantly improve medical care for the crew during long-duration missions.

“This represents a leap in technological innovation,” said Auxilium Biotechnologies Director of Engineering Isac Lazarovits, in the release. “The installation of the printer on the ISS required only two minutes of astronaut time before it was fully operational—an impressive milestone in itself. For the first time, we have achieved a straightforward integration solution for a manufacturing facility in space.

“With AMP-1 now operational, we are advancing our biomanufacturing research and the development of regenerative medical devices at an unprecedented pace, Lazarovits continued. “We extend our gratitude to our partners at Space Tango and Invetech, who have worked closely with us to make this project a reality.”

Auxilium’s use of bioprinting in microgravity builds on NASA’s pioneering legacy in medical innovations, such as the LVAD (Left Ventricular Assist Device), enhanced digital imaging for MRIs and CT scans, and life-saving technologies like artificial heart defibrillators and insulin pumps. According to Auxilium, the AMP-1 “has the potential to revolutionize medicine on both Earth and in space, further advancing space-based manufacturing’s role in transforming medical solutions.”

“These cutting-edge bioprinting capabilities represent the next generation of space-based manufacturing,” the release stated. “By leveraging funding from NASA’s InSpace Production Applications (InSpa) program, Auxilium has emerged as a leader in its category, commanding a strong market position and attracting investor interest. Auxilium’s success underscores the critical role of small businesses in shaping the future of space exploration and commercialization.”