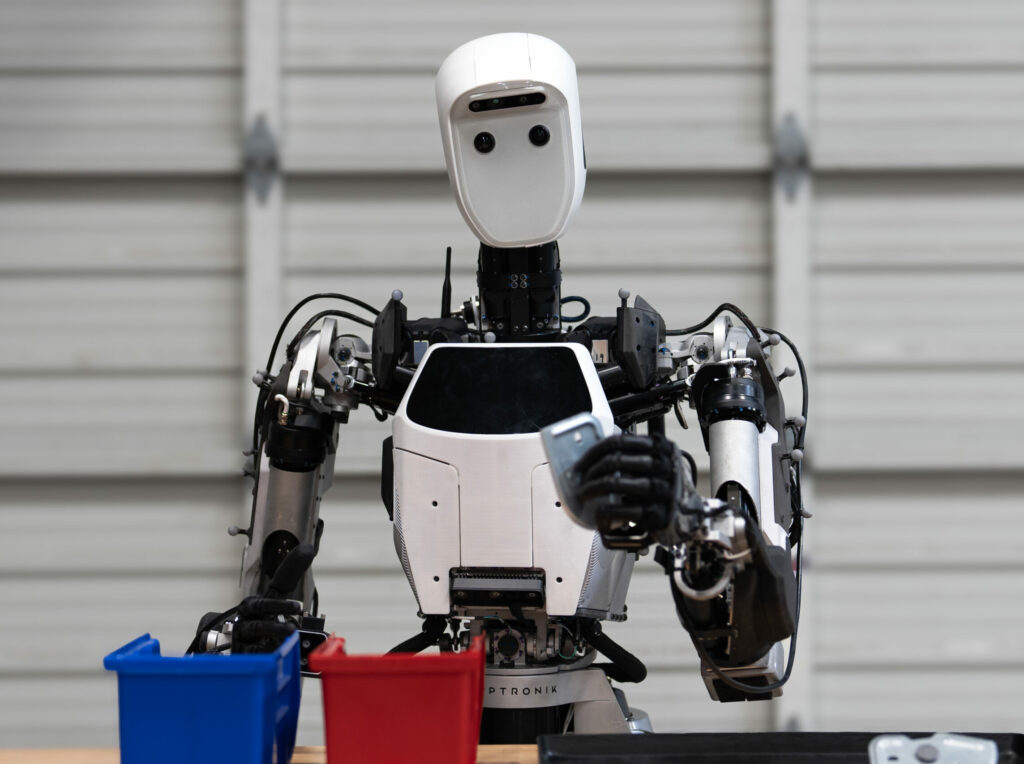

Newly manufactured Apollo humanoid robots will leverage Jabil’s factory environment for real-world validation testing, completing an array of simple, repetitive manufacturing tasks before being deployed to Apptronik customer sites. (Photo: Business Wire)

When humanoids are introduced to Jabil’s manufacturing lines, they will augment and support the existing workforce, the company said.

ST. PETERSBURG, Fla.—Apptronik, an AI-powered humanoid robotics company, and Jabil, a global provider of engineering, manufacturing, and supply chain services, recently announced a pilot and strategic collaboration to build Apollo humanoid robots and integrate them into specific Jabil manufacturing operations. This includes the production lines that will build Apollo humanoid robots, paving the way for Apollo to build Apollo, the companies said in a joint release.

As part of the pilot program, newly manufactured Apollo units will leverage Jabil’s factory environment for real-world validation testing. The robots will be used to complete an array of simple, repetitive intralogistics and manufacturing tasks, including inspection, sorting, kitting, lineside delivery, fixture placement, and sub-assembly, before being deployed to Apptronik customer sites.

When humanoids are introduced to Jabil’s manufacturing lines, they will augment and support the existing workforce. People who may have previously done those repetitive tasks can then dedicate their time to more creative, thought-intensive projects that shape and improve the future of Jabil’s operations, the release stated.

Jabil supports customers in the development of market-leading advanced robotics and warehouse automation, pushing the boundaries of technology. By building and evaluating their function within a best-in-class production environment, Apptronik and Jabil will gather valuable real-world use cases for automation in manufacturing and optimizing Apollo’s AI models.

As the worldwide manufacturing partner for Apollo humanoid robots, Jabil can provide Apptronik the flexibility and agility to scale production around the world as needed. Jabil’s expertise in developing and manufacturing robots will allow Apptronik to unify its supply chain and gain access to Jabil’s advanced manufacturing capabilities around the globe. This collaboration is expected to benefit Apptronik customers through world-class quality, scalability, inventory management, turn-key procurement, and rapid production. At the same time, it will provide Jabil the opportunity to test new automation systems in support of safer operations, greater efficiency, and accelerated time-to-market, the release said.

“We’ve been committed to advanced automation and robotics across our operations, so piloting Apollo is a logical next step for our division and for Jabil in the long term,” said Rafael Renno, senior vice president of global business units at Jabil, in the release. “Not only will we get a first-hand look at the impact that general-purpose robots can have as we test Apollo in our operations, but as we begin producing Apollo units, we can play a role in defining the future of manufacturing. These new technologies and applications further enhance Jabil’s best-in-class capabilities to solve complex challenges and manufacture at scale for our customers.”

To fulfill customer demand for its humanoid robots at the price point necessary for mass adoption, Apptronik’s design includes a heritage of unique actuators, or motors, that are said to unlock affordability and simplify maintenance. Its latest generation of actuators requires a significantly reduced number of components, manufacturing time, and cost compared to previous generations.

With a cost-effective, simplified bill of materials (BOM) and ability to mass produce units at scale with Jabil, Apptronik aims to make general-purpose humanoids more affordable to expand into new markets and roles, such as front-of-house retail, elder care, and eventually, home use.

“Humanoid robots have the potential to revolutionize the way we live and work, but for that to become a reality, we need to be able to build them rapidly at scale, at the right price point, and in geographies where our customers are located,” said Jeff Cardenas, co-founder and CEO of Apptronik, in the release. “Our partnership with Jabil, along with our unique design for manufacturability and ability to have Apollo humanoid robots handling material movement and assembly tasks in the factory, are critical components needed to create a flywheel effect that could make humanoid robots ubiquitous.”

Apptronik started out of the Human Centered Robotics Lab at the University of Texas at Austin, and today has more than 150 employees. The company describes itself as a human-centered robotics company that develops AI-powered humanoid robots. Its goal is to create human helpers to support humanity in every facet of life.

“Our robot, Apollo, is designed to collaborate thoughtfully with humans—initially in critical industries such as manufacturing and logistics, with future applications in healthcare, the home, and beyond,” Apptronik stated in the release.

Apollo is the culmination of nearly a decade of development, drawing on Apptronik’s extensive work on 15 previous robots, including NASA’s Valkyrie robot.