Combining high torque density with light weight, TQ-Systems USA’s frameless motors are finding applications in medical surgical robots and humanoid robots, among many other applications. (Photo courtesy TQ-Group/TQ-Systems USA)

TQ-Systems USA is working to mimic, in the U.S., the success of Germany-based TQ-Group.

By Mark Shortt

TQ-Systems USA, the North American arm of Germany-based TQ-Group, is an electronics engineering and manufacturing services (E2MS) company that provides everything from product concept to manufacturing, assembly, testing, and certification.

The company, based in Chesapeake, Virginia, is building a strong presence in the United States as a full, turnkey service provider that combines excellence in technology with an emphasis on quality throughout its operations. It recently added a new surface mount device (SMD) line to to its Chesapeake facility to double its production capacity in the U.S.

“Technology in Quality: It’s what TQ stands for and what our customers value most,” said Brandon Aumiller, an aerospace engineer by training who serves as TQ-Systems USA’s Director of Sales for Embedded Products and EMS, in an emailed response to Design-2-Part. “For us, quality extends beyond just the things that we manufacture; it starts with customer service and the desire to always go above and beyond to help our customers make their vision a reality.”

As a full turnkey service provider, TQ supports customers in a long list of industries, from medical and robotics to aviation, agriculture, IoT, and industrial automation, to name a few. Its team can help customers from their initial product idea to full series production and after-sales support, including obsolescence management.

“From PCB assemblies to full system integrations; frameless motors to e-bike drives, the products we produce for our customers are just as diverse as the industries we serve,” said Aumiller.

Among the company’s strongest offerings are its embedded computer modules, which integrate into its customer’s designs and are said to typically reduce time to market by six to nine months, and its frameless motors, which combine light weight with high torque density to give customers greater flexibility in their product designs.

“For customers currently designing any sort of robotics applications, from medical robots to automation systems to humanoids, our frameless motors from our RoboDrive Division deliver the highest torque density on the market,” said Aumiller.

Brandon Aumiller and his colleague David Hastings, Director of Sales for Drive Products, spoke with Design-2-Part in February about TQ’s work for industries that place a premium on quality. Following is a transcript of our conversation, edited for clarity and length.

Design-2-Part: Let’s start by talking a little bit about what TQ-Systems USA does. What services does the company provide?

Brandon Aumiller: TQ started out in 1994 as an electronics manufacturing services company. Right from the beginning, they added engineering services, and that’s why we call ourselves an E2MS (electronics engineering and manufacturing services) company. We do everything from components sourcing to PCB assemblies to full, turnkey system assemblies, aftermarket sales and support, obsolescence management, and a few other things around those types of systems and assemblies, including embedded computer modules, frameless motors. We have automation devices, we have e-bike motors, and the list goes on.

D2P: Do you have other production sites in addition to your U.S manufacturing operations in Chesapeake, Virgina?

BA: Currently, Chesapeake, Virginia, is the only manufacturing location we have in the U.S. We are constantly working on expanding our capabilities here. We recently added a second SMD line to double our capacity here in the U.S. and we’re also looking into building an additional facility in the States. We’re hopeful that will move forward in the next one or two years.

D2P: What would you like OEM engineers and purchasers to know about the capabilities, services, and technologies that your Chesapeake facility offers?

David Hastings: From my side, certainly, our drives and frameless motor technology are sold out of our Chesapeake location. We work with some of the largest medical companies in the world, and some of the biggest DoD companies, too. We do a lot of applications in robotics, including humanoid robots, that are sold from this location. We work hand in hand with TQ-Group, so it’s not like they’re a separate company. In my area of drives and robotics, we in the U.S. pair with our teams in Germany to work on every one of those projects together.

BA: Let’s put it this way: In Europe, TQ Group is one of the top 10 contract manufacturers for electronic assemblies, and we aim to bring the same level of service and support to the U.S.

That includes providing the highest level of customer satisfaction, customer service, and quality. We prove that by being certified not only to ISO 9001, but also ISO 13485 and, in aviation, AS9100. We’re also certified to ISO 50001.

D2P: Do those certifications apply to Chesapeake?

BA: Currently, only ISO 9001 applies to Chesapeake, specifically. But as soon as the new facilities come online, we will bring those additional certifications. We’ll certify this location, as well, for the certifications I just mentioned.

D2P: One of TQ-Systems USA’s white papers mentioned the importance of speed to market in the medical industry. How does your team strike that balance of meeting the need for speed to market without sacrificing quality?

BA: We operate out of what we call customer centers, where we have dedicated groups of production engineers, purchasing, inside sales, and an account manager, who jointly take care of the account to make sure that from the time we receive an RFQ from a customer, until they receive a quote back from us, everything runs smoothly, efficiently, and everyone is involved from the beginning.

It’s a small community within the company that takes care of the customer jointly. So there’s no friction when handing stuff over from sales to the purchasing department, or to the production team. Everything is situated in one group, grouped together, and those four people take care of the account together and make sure that everything is carried through production and out the door to the customer, as smoothly and as quickly as possible.

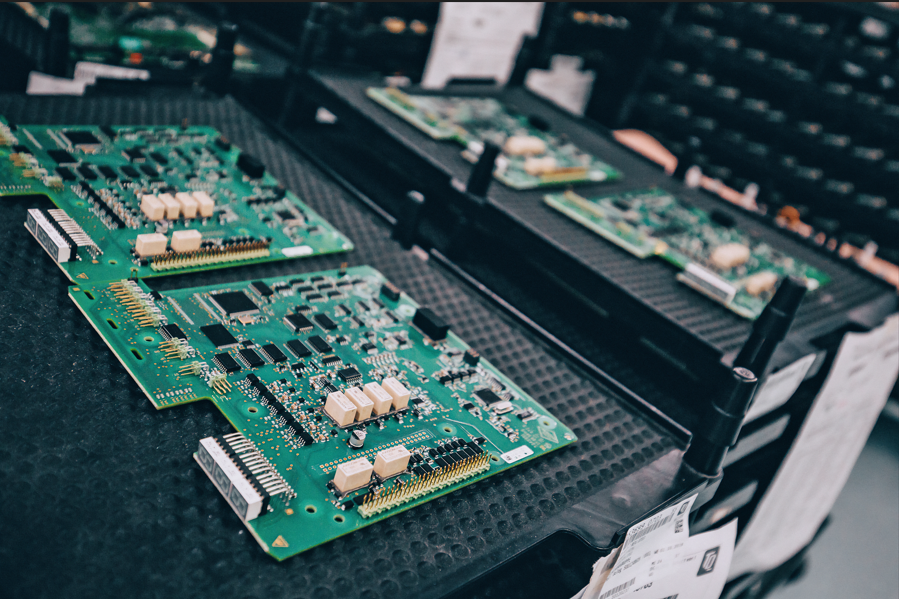

Electronics engineering and manufacturing services are a core strength of TQ-Systems USA, which recently added a new SMD line to its facility in Chesapeake, Virginia. (Photo courtesy TQ-Group/TQ-Systems USA)

D2P: How would you describe the medical product industry today, in terms of technology trends and how it’s evolving, and how that affects what it requires to succeed in this industry?

DH: Many medical companies are looking for a motor that’s flexible to their application. I’m referring to the design.

For instance, we have a rotor, a stator, a kit that’s put together inside of an actuator. Medical companies can design their specific robots around those motors. For example, if you want to run wires through the middle, or if you want to hide different parts of the application inside of that, you can use those motors.

With our frameless motor technology, we have one of the highest torque motors on the market. But we also have one of the lightest-weight motors on the market. So, having such a high torque motor that performs so well at such a light weight—that type of technology is what drives these robotic applications, and these robotic applications are the future in operating rooms across the world.

We have a customer that’s taking our small motors and driving catheters up through the human body, up around the heart, all the way to the brain, and they’re they’re clawing blood clots out of a person’s brain to prevent strokes. So these types of technologies are really what’s evolving, and why robotics is exploding in the medical industry.

BA: In the electronics space, I would add that we all know that getting medical devices certified through FDA and other regulatory bodies takes a long time. So any mistake and any new iteration or revision of any device should be avoided wherever possible. And so we use our expertise in engineering services to guide our customers, to help them make smart design decisions, to assure longevity and, especially, component availability, right from the beginning, so they won’t have to worry about going through recertifications and things like that, down the line.

D2P: David, I read your whitepaper on the frameless motors, and it described the motors as highly dynamic from a technical standpoint, but also adaptable to changing and growing requirements. How are the motors both dynamic and adaptable?

DH: With our frameless motor technology, the design capabilities are endless. You can directly attach the motor to a stack, and it can be put into any housing. Our two different series are either shelf fit or glued in. So, the adaptability of our motors to be able to do any application is, I would say, endless at this point.

It has to do with the design and the application. When it comes to our motors, specifically, how compact and how lightweight they are, in relation to the torque density that they can provide for their size, that’s what really gives you the endless design capability.

D2P: What are some of the critical unmet needs in medical manufacturing today that your products, such as the embedded computer modules and the frameless motors, are able to address effectively?

DH: A lot of companies need high torque and low cogging. So when it comes to specific applications, our frameless motors are really superior.

BA: And when it comes to embedded modules, it’s the flexibility and scalability that we provide to our medical customers to design. By using an embedded module inside, they have the flexibility to offer different levels of performance within the same system.

If we use a smart module, for example, you can scale all the way from an Arm-based NXP i.MX 8 all the way up to an Intel based Quad Core Atom or i3 Processor. So different technologies are being enabled within the same system, which, in turn, enables our customers to provide greater flexibility to their customers to meet their specific price points or enable different features to cater to whatever their customer demand is.

D2P: Can you talk a little bit about how the embedded modules are able to shorten development time and also provide AI-supported evaluation of higher amounts of data that’s required in these components now?

BA: Yes. Our embedded modules typically shorten the design cycle by 9 to 15 months, depending on the application and the complexity. You can imagine how complex it is to wire up a CPU these days, with all the different power rails and requirements and tray slips. We take care of this: We include memory and storage devices, all the power rail certifications, so all of that is taken care of already.

Then through a proprietary pin-out where, by following certain industry standards, our customers can connect that embedded module to a baseboard that always follows a specific design guide, if you will. By taking out, let’s say, the hard part of wiring up the ‘brain,’ getting all the connections of the CPU right, that takes out the majority of the design work for the their hardware engineers. And then they can jump right into focusing on their application because when they start development, we give them a starter kit that includes a carrier board, the module, a cooling solution, power supply—all the different design files that they need to start their hardware development.

But while they’re doing their hardware design, they can already start on the software layer. So they can work on those things in parallel.

To give an example, without naming any names, we had one customer who received our—we call it a customer info file—that includes the design files for our carrier board, design guidelines, and tips and tricks. They were able to design their own carrier board in house within two weeks.

D2P: Can you tell us more about the benefits of the frameless motors and the embedded modules for robotics, especially medical robotics?

DH: Yes. Just to give you a heads up, we work with some of the largest medical companies in the world that are building medical robots, including those that are in operating rooms.

High torque density, the weight advantage, all of those things are advantages of our frameless motors and why they are perfect for industry. For a lot of applications, torque and weight are going to matter, and so will flexibility of design. Essentially, the frameless motor is going to be low cost and low maintenance because of the way it’s designed.

D2P: I understand that your company supports numerous industries besides medical, including aviation and aerospace and defense, IoT, and others. Can you name the top four or five industries that you serve?

BA: In general, for TQ as a whole, about 30 percent of our customers are from the industrial sector. Another 15 to 20 percent are in new energy and automation. Medical and aviation make up another 15 percent, I believe. The rest includes all the other industries that you can imagine, basically.

D2P: It seems that as emerging technologies take hold, they would open up even more potential applications for your technologies.

DH: Yes, I would say so. The world is going to automate. Everything is going to automation at some point, it seems, and that’s exactly where we’re at.

For industrial automation, we’re working with a lot of companies. Warehouse type companies are going to want to have all kinds of robotic systems—they’re automating their warehouse processes. So, industrial applications are big for us. Agricultural applications are going to be big for us, too, especially on the frameless motor side. And one of our biggest projects in general is the humanoids robots that we’re working on.

D2P: With all these opportunities, do you encounter any challenges to the adoption of your technologies, and if so, how do you plan to counter them?

DH: As far as my business goes, it’s just a matter of which motor they choose. There are endless opportunities because of all the robotic applications and where we’re going, as the world automates. I don’t really foresee us having issues unless a new technology comes out, and then we may have to re-evaluate our position in the field. But right now, it seems like everybody is going with this frameless motor technology for a lot of projects.

BA: Especially for the robotics side, I would say it’s just a matter of those individual companies getting their product ready for prime time and ready to hit the market. I think that’s the main challenge for you, David, isn’t it?

DH: Yes. For any robotics application, safety is going to be the biggest issue, so safety certifications are important. But that’s why we work with companies that have the safety certified motor controllers.

D2P: Do you run up against any objections based on cost? Do some companies sometimes say, ‘I can’t afford this?’

DH: Yes, absolutely. It’s like buying a Ferrari as opposed to a different, less expensive car. We’re the highest priced in the market. But the reason why you’re paying for that is you’re getting the specs that are needed.

For one of our lineups, our higher end lineup, we actually have people that are inside our facilities hand winding our motors, which a lot of companies won’t do. They’re literally hand winding these motors so that they’re the tightest copper filled factor they could be, so that we can get our specs.

BA: So to summarize that and speak more broadly for TQ as a whole, we value quality and service above all else. And that comes typically at a little bit of a premium. But this is also why we don’t play in the consumer space. We are looking for those types of customers who value quality the most. We are as competitive price-wise as we can be. But, for example, our current field return rate in the electronics space is hovering around 0.03 percent, and that level of quality comes at a premium, unfortunately.

DH: Yes. I can be very competitive in the market with the motors, but the more expensive motors we have are going to be the ones that the medical companies are probably going to use because of their performance and the way they are built. So they are going to opt for them. Brandon hit it right on the head: We don’t get into any consumer electronics or consumer products that are going to be sold of the shelf. Because our motor is going to take up all our costs in the BOM (bill of materials) compared to what they’re selling them for off the shelf.

D2P: Getting back to humanoid robots, what is it about that type of robot that makes it such a good application for your technologies?

DH: Just the design. They’re trying to get the lightest weight, smallest motors in these joints that can have the highest torque density—power or strength—to be able to lift a box in a warehouse while keeping a pretty light frame. That’s pretty much the technology. When it comes to humanoids, the smaller and more powerful, the better.

D2P: That’s pretty much all the questions I have. Is there anything else you’d like to add?

BA: Just in summary, and to reiterate: We’re consistently trying to grow the Americas market, and mimic what we have in Europe. And currently, we’re about a $500 million company, with roughly 2,000 employees. And 225 of those, roughly, are engineers. So, for a contract manufacturing company, we have a lot of engineering capabilities, which, in turn, helps us with the contract manufacturing side of things because we know how to design products, as well as manufacture them. And I believe that sets us apart from many of our competitors.

DH: Just to add to that: If you think about it, between the embedded modules and the frameless motors, we can help somebody build from start to finish on a project. We can help build a complete robotic arm, let’s say, while using the brains of the embedded modules, using the motions of our frameless motors, and the whole application, from start to finish, can be a TQ product, with all of our products in it. That’s kind of an overview of how we can help most companies with their products.