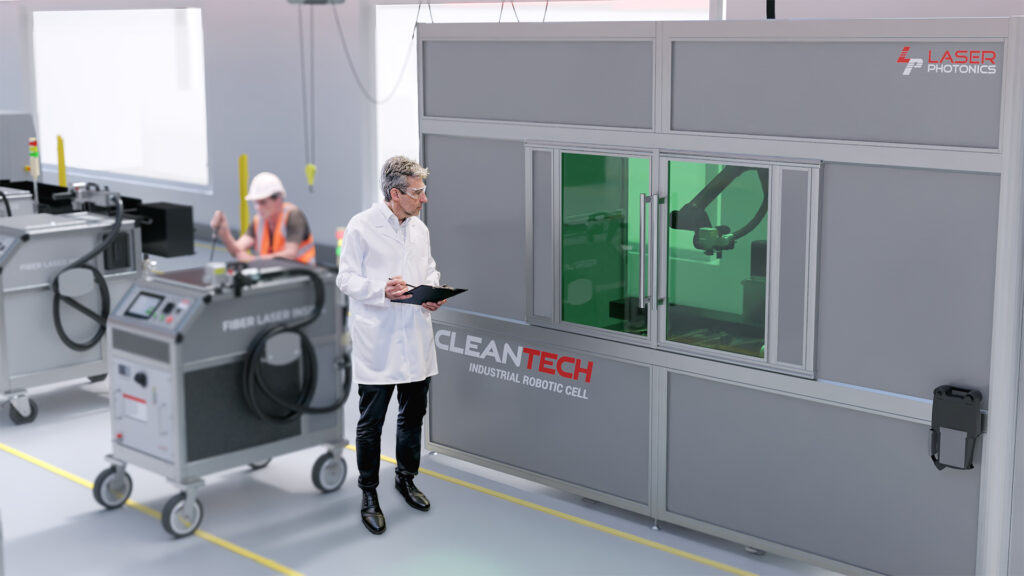

Robotic work cells, equipped with laser-wielding robots and safety features, enable repetitive tasks like laser cleaning to be automated, freeing employees for other tasks. (Photo courtesy Laser Photonics)

According to the manufacturer, enclosed robotic laser parts cleaning systems can safely remove rust and contamination—and they can condition surfaces at dramatically higher volumes—at lower cost than conventional methods.

By Del Williams

Today, advancements in industrial laser cleaning automation show great promise in boosting productivity and safety when rust and contaminant removal or surface preparation is required for higher volumes of components and equipment.

Specifically, combining lasers and advanced robotics within enclosed work cells enables operators to efficiently and repeatedly clean components of different sizes, shapes, and materials on a level said to be previously unattainable through manual methods.

“Automated laser cleaning systems are designed to cost-effectively clean high volumes of even the largest format parts and equipment, and can be tailored to suit the size and complexity of the parts, while eliminating concerns over operator safety,” said Wayne Tupuola, CEO of Orlando, Florida-based Laser Photonics, a global industrial developer of laser systems for cleaning and other material processing applications.

Industrial manufacturers frequently need to remove corrosion, grease, residue, and old coatings—or roughen the surface of metals—prior to coating components and equipment. At times, contaminants or toxic substances need to be eliminated before further processing.

The challenge is that conventional methods like sandblasting, dry ice blasting, and chemical stripping are messy and time- and labor-intensive—including preparation and cleanup—and require costly consumables. These methods can also pose risks to applicators and the environment, and so they are scrutinized by regulators like OSHA and EPA.

A More Efficient Alternative

As a much more efficient alternative, a laser cleaning robotic work cell usually consists of at least one laser-wielding robot, controllers, and safety equipment in a custom, see-through enclosure. These collaborative robots, or cobots, excel at tasks like the laser cleaning of parts that involve repetition, freeing up employees to work on other activities.

The CleanTech Robotic Cell from Laser Photonics, for example, uses a robotic arm that holds a “laser gun” with cleaning, roughening, and finishing capabilities. The robotic arm is programmable via a tablet/controller, where the operator would input the coordinates for material processing. The cleaning laser can be replaced with a welding or cutting laser. If required, the work cell can be split into two sections—the robot cleans on one side, while an operator installs a part to be cleaned on the other side.

“The operator can lay out several components for cleaning over the flatbed, set the cleaning coordinates, and leave the robot processing,” explained Tupuola.

He pointed to advancements in laser technology that complement and expedite the efficient cleaning of such shapes.

“Dual-axis laser technology enables the cleaning of target areas more effectively and quickly if they are complex and uneven,” added Tupuola. “Plus, our proprietary technologies allow the laser to move in various directions and clean hard-to-reach areas.”

Laser Photonics’ CleanTech Titan FX offers up to a 6-foot by 12-foot work envelope for automated laser cleaning, rust removal, and surface conditioning. This industrial, turnkey laser cleaning giant can operate as a standalone unit or be easily integrated into a production line environment, according to the manufacturer.

“Large-format automated laser cleaning systems can expedite the processing of [applications like] automotive tire rims, molds, oil and gas flanges, or even sheets for the hull of a ship or other vessel,” said Tupuola.

“Large-format automated laser cleaning systems can expedite the processing of [applications like] automotive tire rims, molds, oil and gas flanges, or even sheets for the hull of a ship or other vessel,” said Tupuola. He noted that the size and configuration of the enclosures can be customized to accommodate the size and nature of the parts that require cleaning, with the lasers operating at a range of power levels.

Boosting Safety for Operators and the Environment

Another significant benefit to such automation is improved operator and environment safety.

“For extra safety, our custom-tailored automated laser systems are enclosed in a Class I safety work cell. We can also integrate dust and residue collection, as well as a fume extractor that captures vapors during the cleaning of toxic substances,” said Tupuola.

This type of advanced laser cleaning equipment is designed to accommodate rigorous safety regulations. As an example, Laser Photonics’ CleanTech systems are reported to help businesses achieve compliance with OSHA regulations and make environmentally responsible decisions in accordance with EPA’s waste management guidelines.

Abrasive sandblasting involves forcefully projecting a stream of abrasive particles onto a surface, usually with compressed air or steam. The silica sand used in abrasive blasting typically fractures into fine particles and becomes airborne, which can cause serious or fatal respiratory disease. Particles from the coatings, plating, anodizing, corrosion, and even lead paint that are being removed can also be inhaled. To avoid breathing in particulates, operators must wear full HEPA suits when sandblasting.

With chemical stripping, harsh chemicals are used to strip metal-based objects of paint, rust, and other contaminants to bare metal, potentially exposing operators to corrosive acids and noxious chemical fumes. In addition, disposing of toxic chemicals is costly and closely regulated. Laser cleaning seeks to solve or minimize these issues.

The new technology integrates lasers with advanced robotics within enclosed work cells, allowing for efficient, repeatable cleaning of components of various sizes. (Photo courtesy Laser Photonics)

“Installation and programming are needed, but once it’s set up, robotic cell cleaning is fast, precise, thorough, and controlled. So, it’s a very convenient, optimized process if the parts being cleaned are the same,” said Tupuola.

Optimizing the Parts Cleaning Process

Unlike conventional methods, the laser cleaning systems require no consumables other than electric power, minimal labor, and minimal maintenance. The longevity and low-maintenance design of these industrial-grade robotic laser cleaning systems are said to further add to their value, increasing return on investment (ROI) and making replacement unnecessary for decades.

Programming the laser ablation procedure with a cobot work cell can be accomplished with a touchscreen. Generally, programming includes setting coordinates for the sample, ablation pattern, power output, and cleaning speed, according to Tupuola.

“Installation and programming are needed, but once it’s set up, robotic cell cleaning is fast, precise, thorough, and controlled. So, it’s a very convenient, optimized process if the parts being cleaned are the same,” said Tupuola.

Tupuola added that Laser Photonics is now working on integrating 3D scanners into the robotic work cell. This would automate the focusing of the laser and eliminate some of the programming now done by an operator.

While precision laser-based systems have been effectively used to remove rust, residues, contaminants, and paint, this approach commonly involves manual labor. Automated robotic laser cleaning systems provide manufacturers safer, easier, more eco-friendly options.

To meet demand more efficiently, a growing number of manufacturers across a wide range of industries are expected to increasingly turn to these laser systems to cost-effectively clean higher volumes of components with the control and speed required for decades to come.

Del Williams is a technical writer based in Torrance, California.