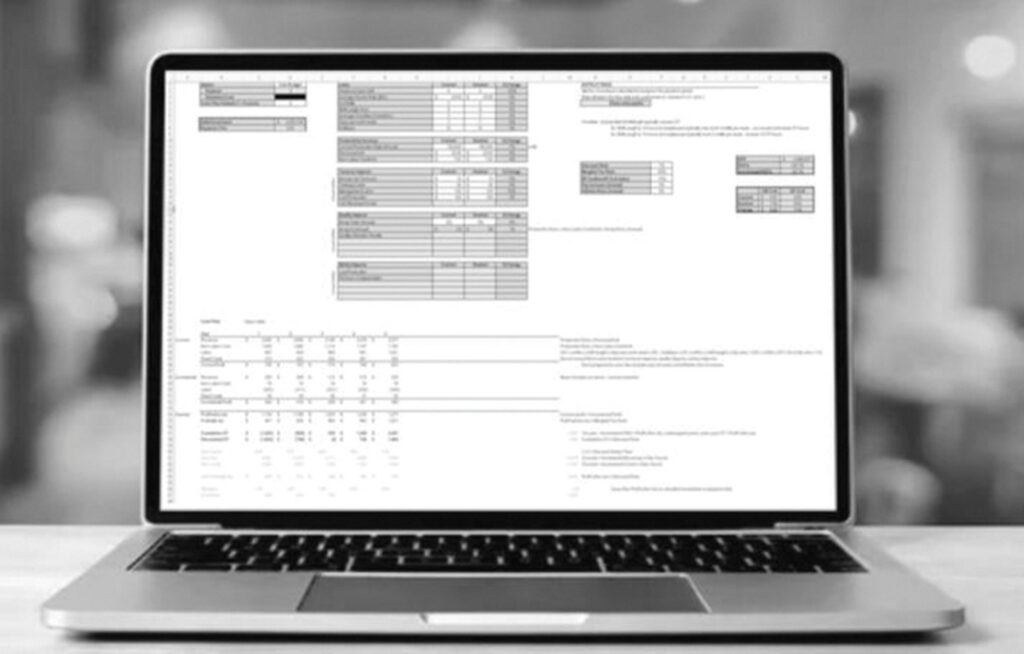

McAlister Design & Automation uses proprietary financial modeling tools to give clients a holistic understanding of the total cost of ownership (TCO), calculating ROI and payback periods for various automation investment options. (Photo courtesy McAlister Design & Automation)

If you’ve decided to automate your manufacturing, your choice of the right integrator is crucial to achieving return on investment goals.

By Joseph Garcia

The journey towards implementation of manufacturing automation can seem daunting, especially when it involves complex technical processes and, oftentimes, significant capital investment. This is precisely where selecting the right integrator becomes pivotal to achieving your return on investment (ROI) goals. An integrator is not just a vendor but a strategic partner who helps align your automation goals with your broader business objectives.

Choosing the right integrator involves consideration of various factors. Foremost among these is the integrator’s technological competence along with experience and proficiency in your industry. They should demonstrate an in-depth understanding of the automation technology landscape, including the latest innovations, while also being aware of the unique challenges and opportunities within your business sector.

An integrator’s capacity to innovate is another crucial consideration. The world of automation is continuously evolving, with new technologies and methodologies emerging regularly. Your chosen integrator should be at the forefront of these trends, ready to leverage the latest innovations to enhance your operations. They should not only be aware of modern automation technologies but also be able to evaluate their applicability to your business and integrate them into your existing workflows seamlessly.

Collaboration

However, the selection process is not merely confined to assessing technical expertise. An integrator’s real value is tied to their personnel. They need to have a team capable of working hand-in-hand with you, fostering an environment of open communication and partnership. A good integrator will not only guide you through the technical intricacies of automation but will help you align your business objectives with a solution that optimally supports your long-term business strategies.

A successful collaboration with your integrator hinges on effective communication. They should be able to clearly articulate complex technological concepts and translate them into terms related to your business objectives—while simultaneously listening to your concerns, understanding your needs, and responding with clear, practical solutions. Open and ongoing dialogues are critical to ensuring you and your automation partner maintain alignment to the priorities established for the automation implementation.

Comprehensive Analysis

Effective integrators not only aid companies in defining and prioritizing objectives but also help clients gain a holistic understanding of the total cost of ownership (TCO). By thoroughly analyzing the direct and indirect costs associated with manual operations and exploring potential automation solutions, accurate calculations of ROI and payback periods for different automation investment options can be made. This comprehensive approach ensures a well-informed decision-making process.

Often, the initial costs of implementing automation represent less than half of the total cost of ownership. While equipment acquisition may be the more visible expense, factors such as maintenance, repair, and operations (MRO) costs significantly contribute to the TCO. Regular maintenance, unexpected repairs, and ongoing operational costs, including power consumption and staffing, can substantially add up over time. A successful collaboration with an integrator can provide a clear understanding of these costs, which are crucial in making informed and cost-effective automation decisions.

When considering automation, it is also important to take into account the fully burdened cost of labor to assess automation ROI. This includes expenses related to insurance against accidents and repetitive motion injuries, as well as worker turnover costs, such as training expenses and losses due to the learning curve of new employees.

Furthermore, an integrator can help identify areas where automation can bring significant improvements in efficiency and productivity. By streamlining processes and reducing manual intervention, companies can optimize their operations to achieve higher levels of productivity while minimizing errors and delays.

Tailored Solutions

Successful manufacturing automation solutions will vary greatly between businesses. What might be a great solution for one company could be ineffective or even harmful for another. It’s important to recognize that there is no one-size-fits-all automation solution that applies universally. Each company has its own unique set of priorities based on its resources, market conditions, and long-term goals.

In certain instances, particularly in regulated industries, companies may prioritize product inspection and data-tracking over production rates or solution cost. In contrast, certain companies may prioritize financial returns and implementation speed over technological innovation.

In another scenario, some companies prioritize high production throughput. They focus on maximizing the quantity of products they can produce within a given timeframe. This strategy allows them to meet high demand and generate more revenue. However, there are companies that choose to prioritize flexibility over throughput. For them, the ability to quickly adapt to changes in market demands and product mix is crucial. These companies are willing to sacrifice some production speed to maintain the necessary flexibility.

Diversity of Automation Solutions

Taking into consideration the complex nature of automation, it becomes clear that successful implementation requires an intimate understanding of the unique needs and challenges of a business to tailor solutions to their particular business objectives and constraints. Let’s look at a diverse range of automation solutions that we have created in close collaboration with our clients.

Pharmaceutical and medical device industry. At one end of the spectrum, in the pharmaceuticals and medical device industries, the investment in automation is widespread and easy to justify. Among the benefits of automation are the high quality and consistency of the product and the packaging, as well as traceability. The goal of achieving zero defects is crucial when patient safety is at risk and when the product itself is extremely expensive to produce.

In the life sciences sector, companies are usually willing to invest in sophisticated technological solutions with highly efficient and reliable robotics systems. For example, for a pharmaceutical manufacturer, we developed a system to precisely inspect and package ampules at a rate of 300 ampules per minute and place them into cryogenic canes that are packed into a liquid nitrogen freezer for shipments around the world. A vision system automatically inspects 100 percent of the ampules, rejects non-conforming product, and ensures that only quality product is released for shipment.

We have also worked with a medical device manufacturer that had very different requirements. They produce devices that dispense cyanoacrylate surgical adhesive. We developed an automated system to fill, seal, and inspect containers of glue at 180 parts per minute. We designed the system using peristaltic pumps because of the sterility and cleanability of the pump design, the long-proven reliability in very accurately dosing small amounts of fluids, and the ability to handle the thick, viscous glue. This is an example of how the best solution sometimes involves tried-and-true and cost-effective mature technologies.

Warehousing, distribution, and fulfillment. Other companies come to us with very different needs to improve logistical flow—the physical movement of goods from inventory receiving to shipping for maximum efficiency and accessibility. Autonomous mobile robots (AMRs) and autonomous guided vehicles (AGVs) are radically changing the landscape of plants, with relatively low-cost replacements for forklifts and scarce forklift operators.

Cobots. Collaborative robots, often referred to as “cobots,” represent a cost-effective, low-code solution that is transforming manufacturing automation. When implemented for the right applications, these systems often deliver ease-of-use advantages, significantly reducing implementation and operational costs. These advanced systems work alongside human operators, taking over repetitive or potentially hazardous tasks.

This combination of enhanced productivity, improved safety, and reduced costs greatly contributes to a compelling return on investment, making cobots an increasingly popular choice for businesses looking to leverage the benefits of automation while promoting collaboration.

A Valuable Partner

In summary, a competent integrator serves as a valuable partner in guiding companies towards effective decision-making. Through a holistic approach to understanding priorities and considering the total cost of ownership, companies can leverage automation to enhance their operations, improve productivity, and more confidently achieve an optimal return on their automation investment.

Joseph Garcia is vice president at McAlister Design & Automation, a Wauseon Machine company.