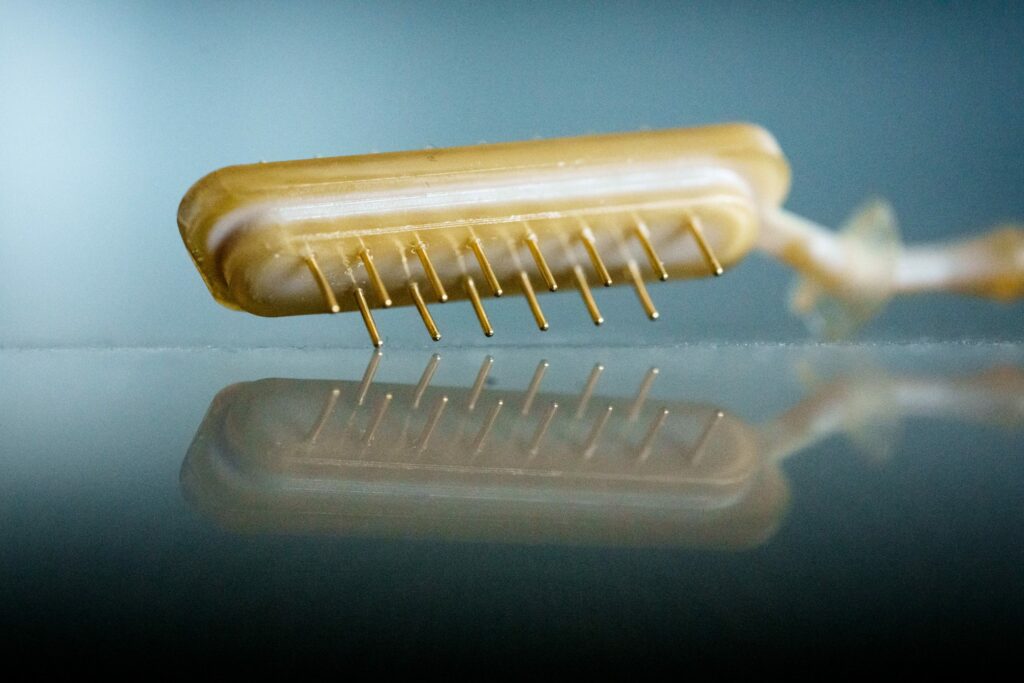

The injection-molded PEEK insert was made using a 3D-printed molding tool at Sandia National Labs’ Advanced Materials Lab. The Rapid Development Connectors Program is focused on fabricating custom electronic connectors for weapons systems in less than a month. (Photo by Craig Fritz)

In-House Advanced Manufacturing Techniques Help Meet Mission Needs

Rapid Development Connectors program increases cycles of learning

The following release was originally published by Sandia National Laboratories.

ALBUQUERQUE, N.M.—A group at Sandia National Laboratories is transforming how it develops custom electronic connectors for weapons systems. The Rapid Development Connectors program is a five-year National Nuclear Security Administration-funded project to build a team and lab space capable of fabricating and delivering functional connectors in less than four weeks.

The program’s overall goal is to quickly provide production-representative development hardware to customers while working in parallel with commercial suppliers. Currently, obtaining custom hardware from external companies can take a year or longer. By delivering development hardware sooner, the program accelerates cycles of learning and reduces overall program risks.

Launched in October 2022, the program quickly generated interest from customers.

“We’re really excited for the potential impact this project can have,” said Michael Gallegos, the program’s lead mechanical engineer specializing in connectors and lightning arrestor connectors. “We’re constantly expanding our capabilities and the types of work we can take on.”

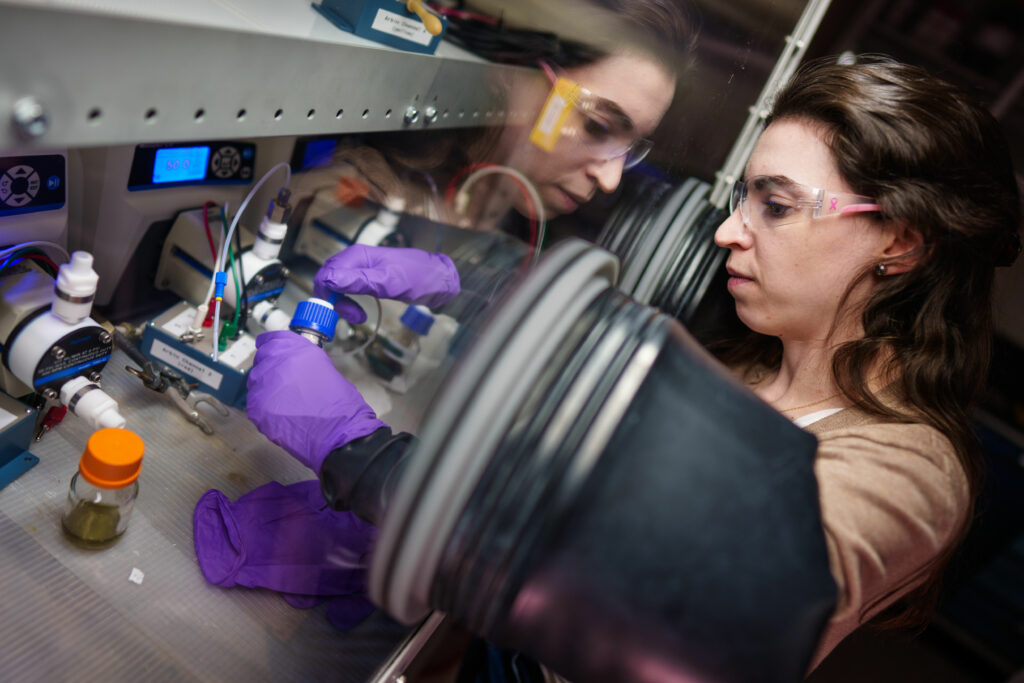

Sandia National Laboratories mechanical engineers and technologists analyze injection-molded PEEK inserts at the Advanced Materials Lab. The recently renovated lab space enables low-volume production of custom electronic connectors. (Photo by Craig Fritz)

Tapping into internal expertise

Sandia’s rapid development connector team is a diverse group of engineers, material scientists, chemists, and product designers from multiple centers across the Labs, enabling them to respond to a wide variety of challenges.

“With this lab, we’re expanding our ability to answer a variety of customer requests and calls,” Gallegos said. “It’s a cross-center collaboration, bridging the nuclear deterrence design and materials sciences worlds. Each project gives us an opportunity to innovate and create functional prototypes using our tools and materials in new ways.”

Along with rapid development comes an opportunity for fundamental research in materials and processes essential for producing electrical interconnects. This understanding of materials science helps identify alternatives that meet performance requirements while being quickly manufacturable.

Expanding space

An advantage to the team is the location of the lab space at the Advanced Materials Laboratory on the University of New Mexico campus outside of Kirtland Air Force Base, making it easier to collaborate with industry partners and universities. Over the past year and a half, the lab space has undergone renovations and been equipped with additive and subtractive manufacturing tools and other machines to fabricate electrical interconnects.

Make it fast, learn fast

Co-locating various manufacturing techniques in the lab has sparked innovative ideas, including combining 3D-printing technology with injection molding for low-volume production of parts. Using additively manufactured molds for injection molding, instead of traditional machined metal molds, enables quick turnaround connector manufacturing with more design iterations.

Other ideas coming out of the lab include hermetic seals made with additive manufactured glass and a green alternative for materials used in lightning arrestor connectors. Gallegos is hopeful the lab space will continue to lead to innovative ideas to reduce lead times.

“We want to provide design engineers the opportunity to test new ideas and think creatively without waiting months for hardware,” Gallegos said. “Our goal is to offer as many cycles of learning for product realization teams as possible.”

Customer feedback

Gabriel Arechederra, who is working on the W93 weapons program, emphasized the Rapid Development Connectors program’s role in producing custom electronic connectors in a short timeframe to reduce schedule risk for programs.

“Working with the Rapid Development Connectors program shortens learning and development cycles, and it is positively impacting our development schedules,” Arechederra said. “Based on requirements, we can tell Michael and his group what we want. He can then provide development parts to us in just days or weeks.”

Having hardware quickly in-hand can help design engineers determine if what they requested is going to work.

“When we have parts readily available, we can better understand features and dimensions, and make design changes quicker to make the best long-term design decision,” Arechederra said. “Having this in-house expertise and capability is extremely valuable to our weapon programs.”

Positive impact

Gallegos said the program’s goal is to provide customers with connectors that are the same or nearly the same as what a supplier would produce and ensure that they are going to function as intended.

“We want to provide the best engineering solution by offering designs to suppliers that we’ve vetted and tested internally,” said Gallegos. “There’s a lot of excitement when people hear about what we do. This project has a lot of potential and we’re eager for the future.”

Jared Dove, Michael’s manager, attested to the program’s positive impact.

“Our customers are seeing the value,” Dove said. “The results are self-evident, and the program is seeing a spike in requests.”

The program’s success has prompted plans to incorporate it into the budget for new weapons programs once the current NNSA funding ends.

Sandia National Laboratories is a multi-mission laboratory operated by National Technology and Engineering Solutions of Sandia LLC, a wholly owned subsidiary of Honeywell International Inc., for the U.S. Department of Energy’s National Nuclear Security Administration. Sandia Labs has major research and development responsibilities in nuclear deterrence, global security, defense, energy technologies and economic competitiveness, with main facilities in Albuquerque, New Mexico, and Livermore, California.

Source:

Sandia National Laboratories battery expert Melissa Meyerson works in a glovebox to set up a lithium-sulfur flow battery. These kinds of batteries have huge potential for being large, safe and in-expensive back-ups for a high-renewables grid. (Photo by Craig Fritz)

Boosting Battery Research

Partnership speeds up development of flow batteries for green grid, water

The following release was originally published by Sandia National Laboratories.

ALBUQUERQUE, N.M.—Most Americans don’t leave home without at least one lithium battery-powered device, and someday, the house itself may have a battery back-up.

Scientists at Sandia National Laboratories are working to make these large back-up batteries less expensive, hold more energy, and be less prone to bursting into flame. One way to tackle all three challenges is by changing up the battery chemistry with the addition of sulfur, according to Sandia battery expert Melissa Meyerson.

“One of the biggest benefits compared to what is on the market today is the energy density,” Meyerson said. “Lithium and sulfur are two of the most energy-dense materials for batteries, and sulfur is incredibly cheap.”

A partnership between technical experts at Sandia and local entrepreneurs facilitated by the Department of Energy’s Boost program aims to get big, safe, stationary lithium-sulfur flow batteries to market faster.

The flow battery design allows for a physical separation of the portions of a household battery labeled with a minus and plus sign. This separation should make the battery safer and less likely to lose charge when just sitting idle, said Leo Small, a Sandia materials scientist who is also part of the collaboration.

“One goal is to make grid-scale batteries: really, really big batteries,” Small said. “One of the objectives we were trying to go after by putting the lithium sulfur chemistry into a flow battery architecture was to physically separate the anode and the cathode to potentially make it safer when dealing with thousands or millions of kilowatt-hours of energy storage.”

One thousand kilowatt-hours is enough to power approximately 33 U.S. households for a day.

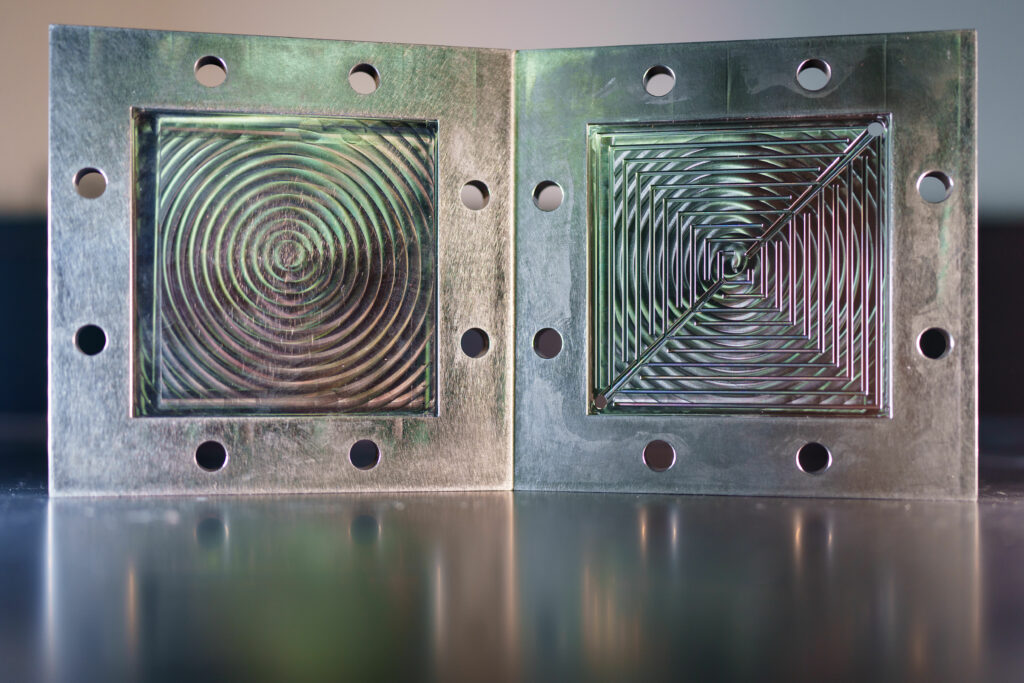

The interior of a lithium-sulfur flow battery being designed at Sandia National Laboratories. A partnership between technical experts at Sandia and local entrepreneurs aims to get these batteries to market faster. (Photo by Craig Fritz)

Building better battery technology

The team’s largest technical hurdle was adapting lithium-sulfur chemistry into a flow battery design, Meyerson said.

The current lab-scale battery, about three inches wide, consists of a solid lithium metal anode, representing the minus sign side of a household battery, and a liquid cathode, representing the plus sign side. When the battery provides electricity, the lithium metal becomes lithium ions. The other side of the battery comprises a complex cathode-organic electrolyte with lithium salt and sulfur bits mixed in, Meyerson said.

On that side, the lithium salt and sulfur become lithium sulfide when the battery provides electricity. Both sides of the battery contain other chemicals that help charging and discharging reactions take place. A pump moves around the electrolyte and these helper-chemicals to restore them to their active form.

As part of the research project, the team developed a new design for the lithium metal anode, allowing the battery to recharge faster, Meyerson added. There is still more work to be done to refine the complex cathode-organic electrolyte mixture to improve performance while possibly reducing costs, she said.

The team also wants to increase the battery’s capacity to store energy by increasing the amount of lithium or sulfur it contains, Small said. Additionally, the team’s entrepreneur-partner is interested in a lab-scale prototype with several cells in series to make a 12-volt battery, he added.

“The things that we’re focused on as scientists aren’t necessarily the priorities of entrepreneurs,” Small said. “They might say, ‘Actually, this thing is driving the cost, so if you could get rid of it, that would be helpful.’ This perspective can help reframe our research and what we should be looking at for increasing the technology readiness level.”

Boosting local entrepreneurship

New Mexico entrepreneur Charles Call was working on a startup company to develop a solar-powered device for producing water from air. He realized that the company needed a reliable battery, capable of storing energy for long periods, allowing continuous water production when the sun wasn’t shining.

Enter the brand-new DOE Boost program.

The DOE Boost program, a collaboration between FedTech, a startup accelerator company, and Sandia, consists of a 16-week boot camp with weekly seminars and coaching sessions by FedTech to help entrepreneurs with their startup companies.

“I have 25 years of experience building startup companies,” Call said. “I went into the program thinking I could probably teach all of these classes, but I learned something new every week. I give a lot of credit to the DOE Boost program for the quality of the sessions and mentors.”

Selected entrepreneurs are paired with Sandia technical experts for technical guidance and discussions during weekly calls. Call’s interest in advanced battery technology led to his pairing with Small and Meyerson.

Midway through the program, there is a practice pitching session, and the program culminates in a pitch session where the winning entrepreneur receives $2,000 towards launching their company and additional technical guidance. Call described the pitching contest as a fun way to encourage entrepreneurs to focus their efforts on preparing their business plan in the face of a hard deadline.

Forging ahead together

Currently, Call is applying for grants and other funding opportunities to continue the partnership, frame the research, and advance the technology’s transition from the research and development stage to the field-demonstration stage as quickly as possible, he said. GridFlow, the startup company, is working on licensing Sandia’s provisional patent to aid them in the funding applications, Small said.

By this fall, Call aims to show the commercial viability of the technology and have a 100-watt or a kilowatt prototype ready for field or home testing.

“I feel we have an almost too-good-to-be-true partnership here,” Call said. “No one on my team is a battery expert, and we’re not ever going to be great chemists like they are, but we have experience in startups, finance, technology, and product development. We especially have a lot of experience building products that have fluidics, and the flow aspect of this technology was the part of the system the scientists were least familiar with.”

The battery research is funded by DOE’s Office of Electricity, while the collaboration was supported by DOE Boost, funded by DOE’s Technology Commercialization Fund and administered by the Office of Technology Transitions.

Source: