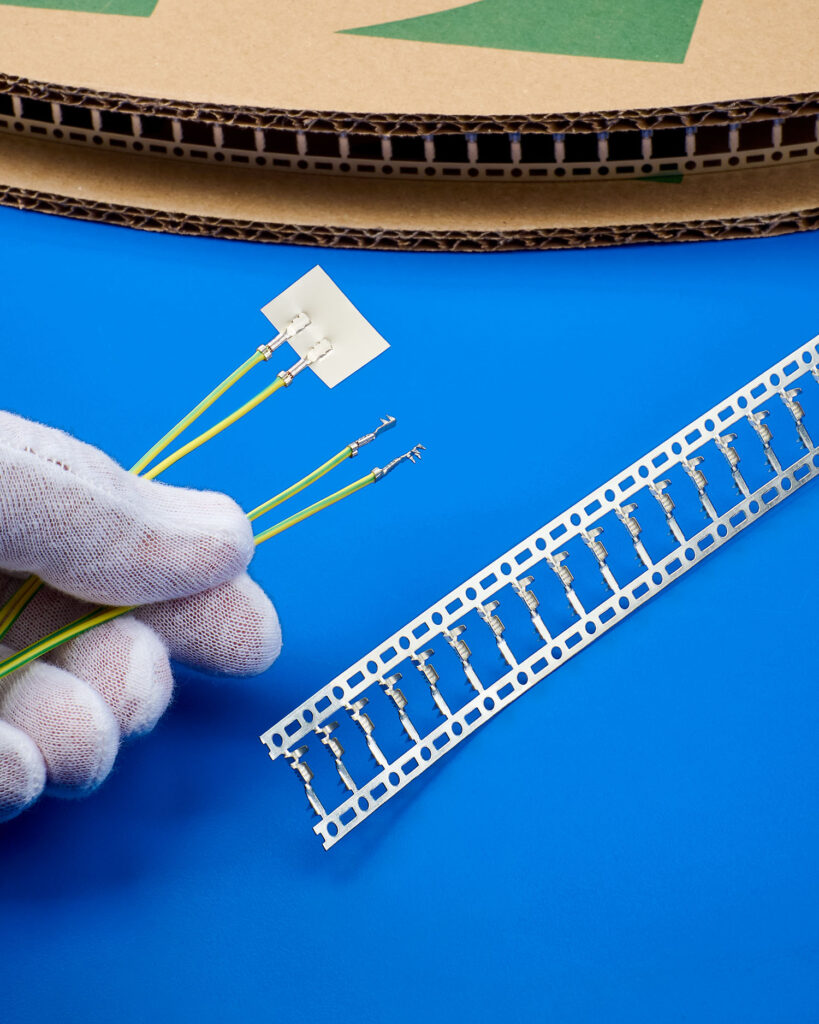

Supplied in strip form on reels, ETCO TFC Thin Film Connectors can be made from brass and tinned-brass in a wide range of custom sizes and thicknesses to precisely match OEM requirements. (Image courtesy ETCO)

ETCO has also rolled out new high-current ring terminals for ultrasonic welded wire attachment.

BRADENTON, Fla.—ETCO Incorporated has introduced a new line of electrical terminals for attaching wires to thin films typically used in flexible electronics, wearables, thin film transistors (TFTs), organic light-emitting diodes (OLEDs), and other devices, the company said in a release.

Suited for attaching 0-6 Ga wire by automated equipment, ETCO BT-Series Heavy-Duty Battery Terminals have an insulation support to bend around the wire jacket insulation. (Image courtesy ETCO)

ETCO TFC Thin Film Connectors are designed to reliably connect 18-22 AWG wire to aluminum- and copper-foil or film laminates from 0.010-inch to 0.025-inch thick, depending upon the substrate. Well-suited for miniaturized applications, the connectors are reported to securely embed into the substrate with lances and incorporate a highly reliable F-crimp for the wire connection.

Supplied in strip form on reels, the thin film connectors can be made from brass and tinned-brass in a wide range of custom sizes and thicknesses to precisely match OEM requirements. According to ETCO, the connectors have been tested to maintain their integrity under various environmental conditions, such as temperature changes, high humidity, and mechanical stresses.

In another release, the company said it also recently introduced a new line of heavy-duty locking ring terminals, especially designed for the secure, ultrasonically-welded wire attachment process preferred in high current applications.

ETCO BT-Series Heavy-Duty Battery Terminals are made from 0.060-inch thick brass or copper for maximum conductivity and are designed to be ultrasonically welded for use in any high current application. Featuring four teeth that extend 0.065 inch from the terminal surface of the ring, their sharp wedges bite into metal and anchor the terminal to help prevent unwanted rotation, the company said.

Suited for attaching 0-6 Ga wire by automated equipment, the heavy-duty battery terminals have an insulation support to bend around the wire jacket insulation. They are reportedly well-suited for virtually any high voltage wiring including EV batteries, alternators, and starters in automotive, AG and construction equipment, process control, and trucking applications.