An automotive speaker grill printed with SAF™ PP on a Stratasys H350™ printer and finished with the VaporFuse Surfacing process using the Powerfuse S PP machine from DyeMansion. (Photo: Business Wire)

The advance could help create a new generation of auxetic products, from better sneaker insoles to blast-resilient buildings.

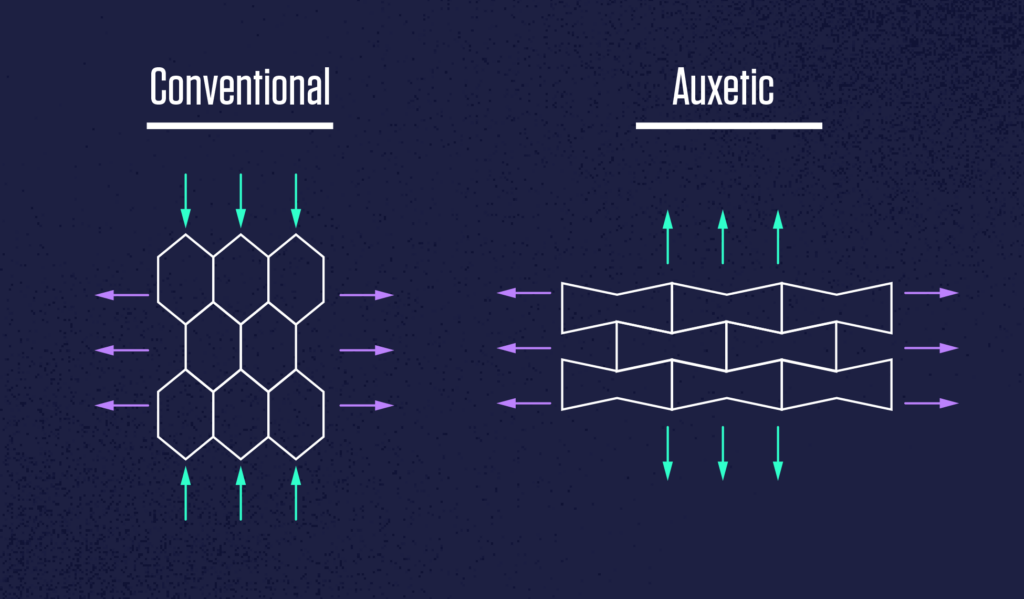

GAITHERSBURG, Md.—Imagine pulling on the long ends of a rectangular piece of rubber. It should become narrower and thinner. But what if, instead, it got wider and fatter?

Now, push in on those same ends. What if the rubber became narrower and thinner?

Such common-sense-defying materials do exist. They’re called auxetics, and they have a raft of unique properties that make them well-suited for sneaker insoles, bomb-resilient buildings, car bumpers, and clothing.

Despite this great potential, auxetic products have been slow to market. Researchers at the National Institute of Standards and Technology (NIST) and the University of Chicago hope to change this.

In a new study published in NPJ Computational Materials, they announced they’ve developed a new tool that makes designing materials with auxetic properties easier and faster. An algorithm, the tool enables precise three-dimensional design of auxetics.

“It’s a huge advance for auxetics,” said NIST materials research engineer Edwin Chan, a study co-author. “We can actually optimize the material to have whatever particular mechanical properties and behavior that you want.”

The behavior of elastic materials is partially described by Poisson’s ratio, which explains how the material changes shape when you stretch or squeeze it in one direction.

Most materials have a positive Poisson’s ratio, which means squeezing them in one direction will make them wider and/or thicker in other directions. Stretching them makes them narrower and/or thinner. Auxetics have a negative value of Poisson’s ratio and do exactly the reverse.

When you punch a nonauxetic material, it gets thinner and expands laterally. When you punch an auxetic, the material bunches up and narrows in width. Under the right circumstances, this provides greater resistance to impact.

For example, if you punch a bag full of water (like you would carry for hiking), the water within it will flow away from the point of impact. If the bag were full of an auxetic foam when you punched it, though, the material would grow denser and stiffen.

This is one of the reasons auxetics are being considered for use in buildings and automobiles. They have the potential to offer greater protection from explosions and collisions. In a sneaker insole, an auxetic gel or rubber foam might better cushion the foot when it strikes the ground.

In clothing, auxetic nylons, fibers, and other synthetic materials could prove more comfortable than traditional materials. Since they widen when stretched, they more effectively distribute pressure across the body, potentially relieving strain on the back, joints, neck, or shoulders.

The design tool devised by the NIST and University of Chicago scientists is an “inverse design” algorithm, which means users can input their desired value for their auxetic material’s Poisson’s ratio. The algorithm then proposes an optimized structure for the material.

Another way of expressing Poisson’s ratio is that it describes the relationship between shape and volume when one of these changes. The new algorithm allows for fine-tuning this relationship to create auxetic materials that behave in ways you couldn’t find in nature.

“Our research is a beautiful example of theoretical, experimental, and computational science working together to realize something new,” said NIST materials research engineer Marcos Reyes-Martinez. “Having a way to make auxetics better will allow them to become more prevalent in our everyday lives.”

The researchers patented the algorithm, as well as the underlying methodology and its implementation, using 3D printing.

Source:

https://www.nist.gov/news-events/news/2024/05/new-way-designing-auxetic-materials