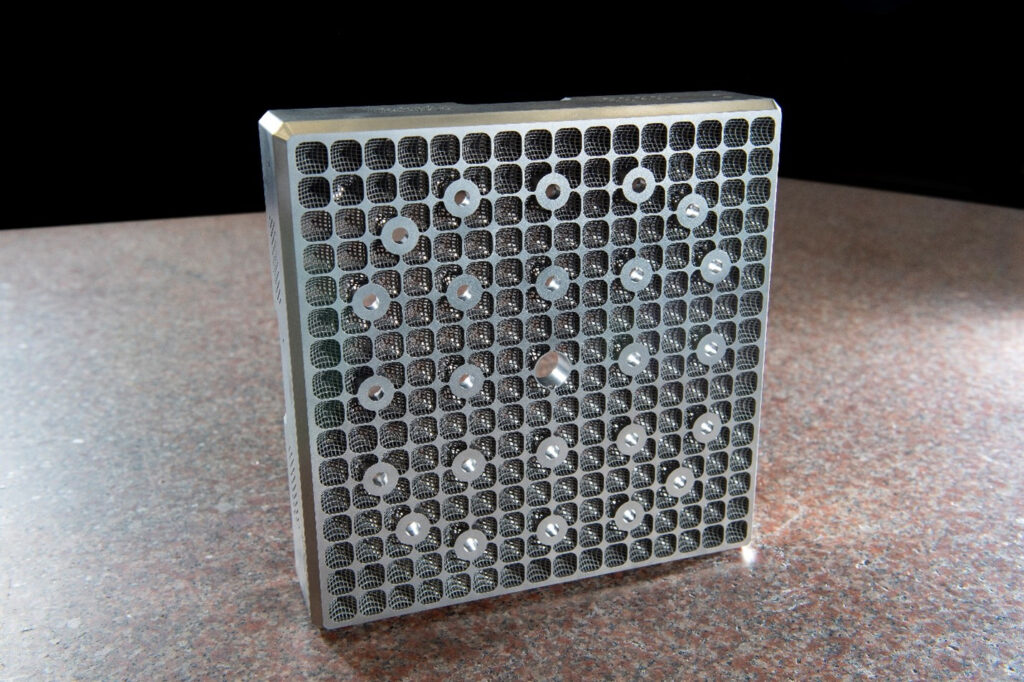

A Westinghouse fuel assembly bottom nozzle that the company fabricated using additive manufacturing. (Photo: Business Wire)

Westinghouse used additive manufacturing to fabricate a fuel assembly bottom nozzle that reportedly increased debris resistance by about 30 percent.

CRANBERRY TOWNSHIP, Pa.— Westinghouse Electric Company said in a release that it used additive manufacturing (AM) to fabricate bottom nozzles that reportedly improved debris capture and fuel endurance within its fuel assemblies. According to Westinghouse, debris-wearing action on the fuel rod cladding—known as debris fretting—is the primary source of leaks in pressurized water reactor (PWR) fuel assemblies.

The nozzles were integrated into four lead test assemblies that were delivered in the first quarter of 2024 to Alabama Power’s Joseph M. Farley Nuclear Plant, operated by Southern Nuclear.

Additive manufacturing technology is reported to offer significant improvements in debris filtering by enhancing design freedom, which reduces the diameter of debris that can enter into the reactor. In testing, the additively manufactured components reportedly demonstrated an approximately 30 percent improvement in debris resistance, from 65 percent to 96 percent.

“Our additive manufacturing technology is allowing us to achieve breakthrough performance with an immediate positive impact for our customers,” said Westinghouse President of Nuclear Fuel Tarik Choho, in the release. “This significant technology innovation for PWR reactors mitigates the risk of leakage in the fuel rods due to the accumulation of debris, strengthening the safety and efficiency of our customers’ operations.”

In the release, Westinghouse said the milestone demonstrates the company’s “leadership in the nuclear industry to achieve cutting-edge solutions using AM techniques.” The company said that in 2015, it conducted the first material irradiation study of additively manufactured nuclear components. In 2020, the company reportedly installed the first safety-related additive manufacturing component, a Thimble Plugging Device, into an operating commercial reactor. In 2024 Westinghouse said it produced the 1,000th additive manufacturing component for VVER-440 Fuel.