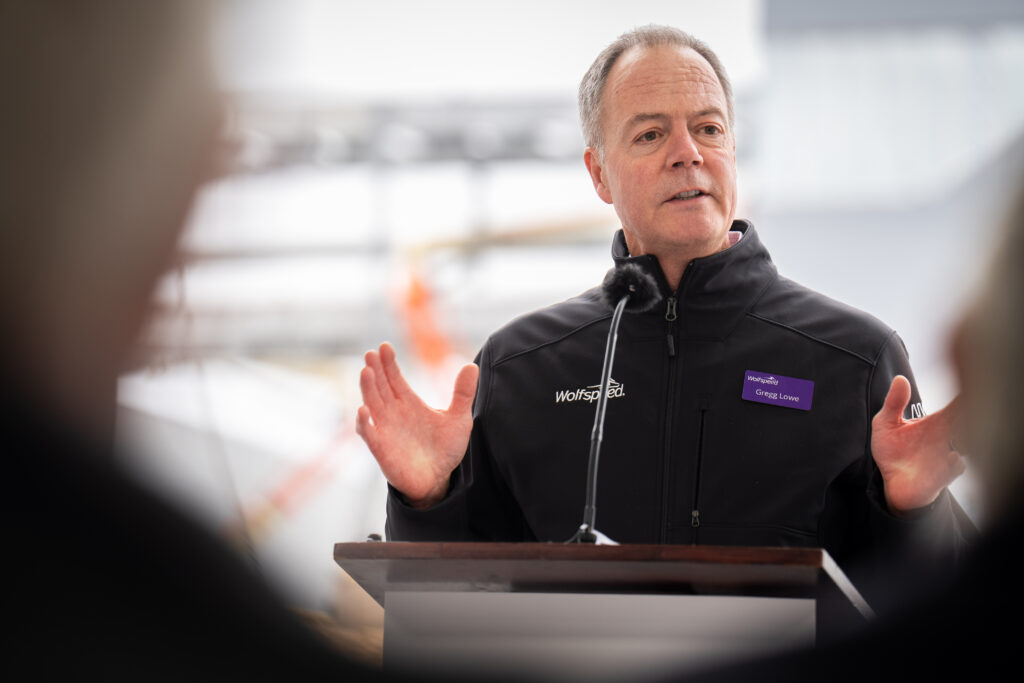

Wolfspeed President and CEO Gregg Lowe, speaking at a ceremony celebrating the topping out of construction at the $5 billion John Palmour Manufacturing Center for Silicon Carbide. (Photo: Business Wire)

The John Palmour Manufacturing Center for Silicon Carbide is a $5 billion investment that will bring jobs and economic growth to the state, the company said.

SILER CITY, N.C.—Silicon carbide technology company Wolfspeed, Inc., reported that it topped out construction at the $5 billion John Palmour Manufacturing Center for Silicon Carbide in Chatham County, North Carolina. The facility, known as “the JP,” will produce 200mm silicon carbide wafers, significantly expanding Wolfspeed’s materials capacity. It is expected to meet the demand for next generation semiconductors that are critical to the energy transition and AI, the company said in a release.

The company hosted Senator Thom Tillis and other local officials, community partners, and employees at a ceremony to celebrate the milestone.

“We are excited to mark this critical milestone alongside our hard-working team, loyal customers, community partners, and ardent supporters like Senator Thom Tillis,” said Wolfspeed President and CEO, Gregg Lowe, in the release. “This facility is a testament to Wolfspeed’s commitment to our local community and domestic workforce, furthering our position as the global leader in silicon carbide production.”

The John Palmour Manufacturing Center for Silicon Carbide represents a total investment of $5 billion, complemented by public and private support. The investment is intended to help accelerate the transition from silicon to silicon carbide and to ramp up supply of the material, which was recently deemed as critical to the energy transition by the U.S. Department of Energy. Phase one of construction is expected to be completed on the 445-acre site by the end of 2024, the company said.

“The JP will help maintain America’s lead in energy innovation and unlock significant benefits for our local community by growing the state’s economy by more than $17.5 billion over the next two decades and creating 1,800 good-paying jobs by 2030,” Lowe added.

The ramp of the JP will support recently signed customer agreements with Renesas, Infineon, and additional companies, while driving meaningful progress towards Wolfspeed’s long-term growth strategy. The manufacturing center will primarily produce 200mm silicon carbide wafers, which are 1.7 times larger than 150mm wafers, translating to more efficient wafers and, ultimately, lower costs, according to the release. The JP “underpins Wolfspeed’s vision of accelerating the adoption of silicon carbide semiconductors across a wide array of end-markets and unlocking a new era of energy efficiency,” the company said.

“Wolfspeed’s $5 billion investment in Chatham County is another example of why North Carolina is the best state in the country to do business,” said Senator Tillis in a statement. “I was proud to vote in favor of the CHIPS and Science Act, which provides critical support for domestic semiconductor manufacturing, and I applaud Wolfspeed’s commitment to developing technology here in North Carolina that supports our national security and economic interests.”

Wolfspeed said it currently produces more than 60 percent of the world’s silicon carbide materials at its Durham, North Carolina headquarters, and is engaged in a $6.5 billion capacity expansion effort to dramatically increase production.