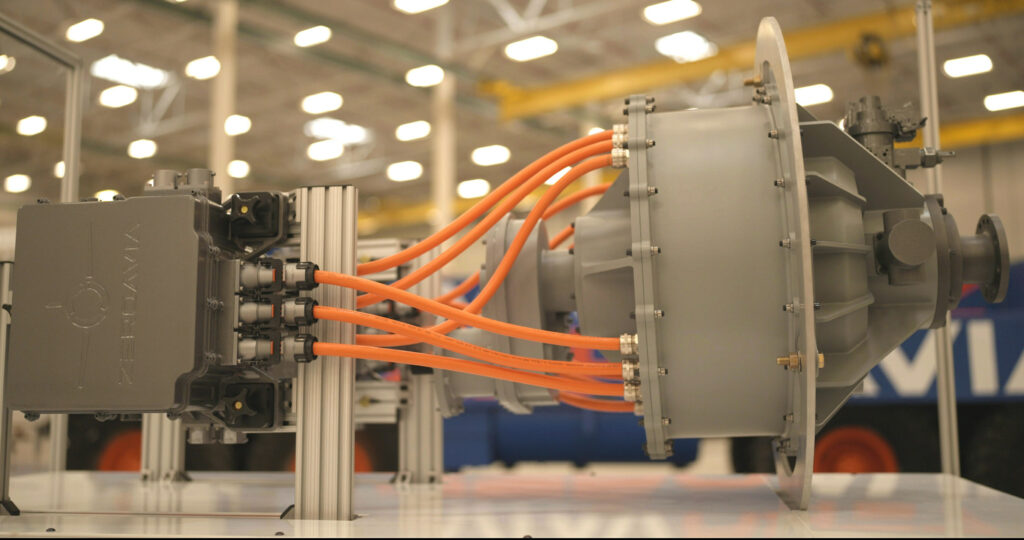

ZeroAvia’s electric propulsion system: the ZeroAvia inverter and 600kW electric motor. (Image courtesy ZeroAvia/PRNewswire)

ZeroAvia will produce full engine systems at the new facility, as well as electric and hydrogen aviation components for OEMs interested in its fuel cell, power electronics, compressor, and electric motor technologies.

EVERETT, Wash.—ZeroAvia, an aircraft engine systems manufacturer working to enable zero-emissions flight, recently opened a new 136,000-square-foot Propulsion Center of Excellence manufacturing facility at Paine Field in Everett, north of Seattle, to support production of power electronics and electric motors.

The company also said in a release that it will offer some of its key components—which the company designed for its hydrogen-electric engines—to other clean aviation innovators. In addition to producing electric propulsion systems for ZeroAvia’s own powertrains, the new plant will manufacture the components that the company offers to customers.

The move allows ZeroAvia to build upon the market for its hydrogen-electric powertrain family while maximizing its investment in R&D and its strategy of vertical integration. Certification work for ZeroAvia’s ZA600 engine (for aircraft with up to 20 seats) is underway, and the underpinning technology for its ZA2000 engine (for aircraft with up to 90 seats) is in advanced development. ZeroAvia is also planning a separate facility—a Hydrogen Center of Excellence—that will focus on producing hydrogen fuel cell systems, the company said.

After conducting market research, ZeroAvia said it identified “significant opportunity” in its advanced electric motors for aviation, including a 660 kW max-power direct-drive motor, capable of speeds up to 2,200 rpm, and the HyperCore 900kW modular motor, capable of speeds up to 20,000 rpm.

The company is also eyeing market opportunities for components such as its silicon carbide inverters; low-temperature proton exchange membrane (LT-PEM) fuel cell configurations; high-temperature PEM (HT-PEM) fuel cell stacks and full power generation systems; and an aviation fuel cell compressor that is reportedly capable of supporting up to 900 kW fuel cell applications at altitudes up to 15,000 feet.

At a ribbon-cutting ceremony attended by Washington State Governor Jay Inslee, U.S. Representative Rick Larsen, and U.S. Representative Suzan DelBene, guests toured ZeroAvia’s new facility, getting a glimpse of how it will support the manufacture of its electric propulsion systems and house the company’s existing R&D operations at Paine Field.

“Today we set forth plans that detail how we are going to bring our engines to market for commercial aircraft, as well as the additional market potential in components generated by our pursuit of aerospace-applicable fuel cell and electric propulsion technologies,” said ZeroAvia Founder and CEO Val Miftakhov, in the release.

“We intend to secure as much market share for commercial aviation propulsion systems as possible, as this will enhance shareholder value and ensure we deliver in tackling climate impact in the sector. While the market for our powertrains is thousands of engines across commercial aircraft, there will be other applications that are not strategically aligned with our full engine offering, but where our technologies can play a major role in the supply chain for other OEMs.”

ZeroAvia said it is in active discussions for potential business with companies working on electric and hydrogen aviation innovations. The company has reportedly signed “a number of key engineering partnerships with major aircraft OEMs and has nearly 2,000 pre-orders for engines” from major global airlines.