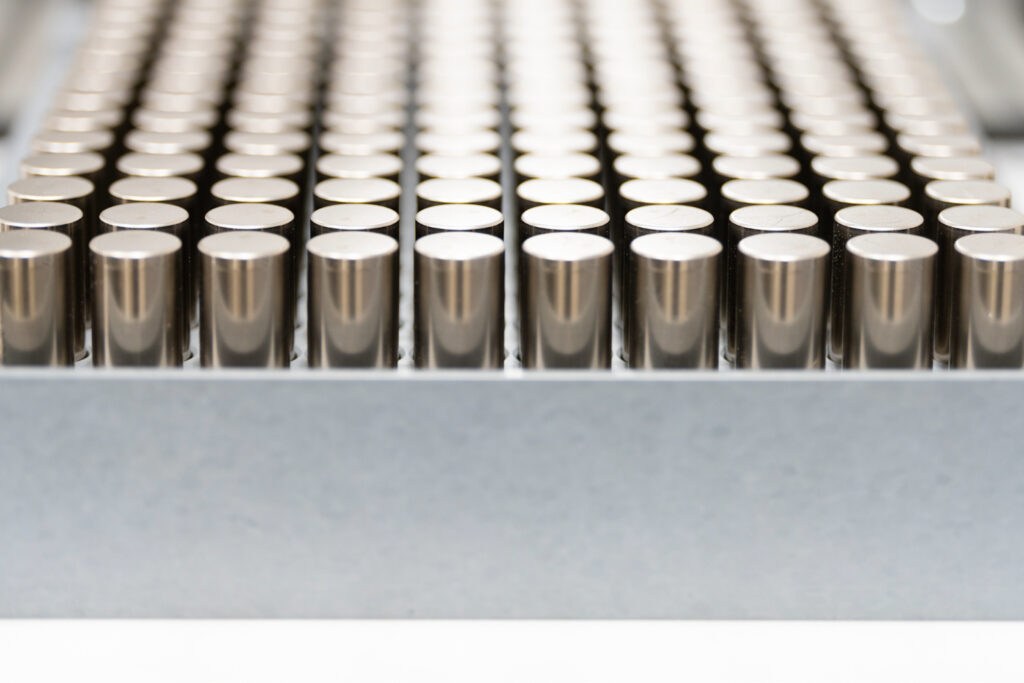

Archer’s battery packs use cylindrical cells that are reported to have a track record of safety, performance, and scalability. (Photo: Business Wire)

The company’s manufacturing team installed an automotive-style line designed for high-volume production, with a reported capability of producing up to 15,000 battery packs per year.

SANTA CLARA, Calif.—Archer Aviation Inc., a designer and developer of electric vertical takeoff and landing (eVTOL) aircraft, recently completed the buildout of its high-volume battery pack manufacturing line at its Integrated Test Lab and Manufacturing Facilities in San Jose, the company said in a release.

The facility will reportedly provide the necessary throughput to support Archer’s plans to ramp up high-volume aircraft production at its manufacturing facility in Georgia, which remains on track to be completed later this year, the company said.

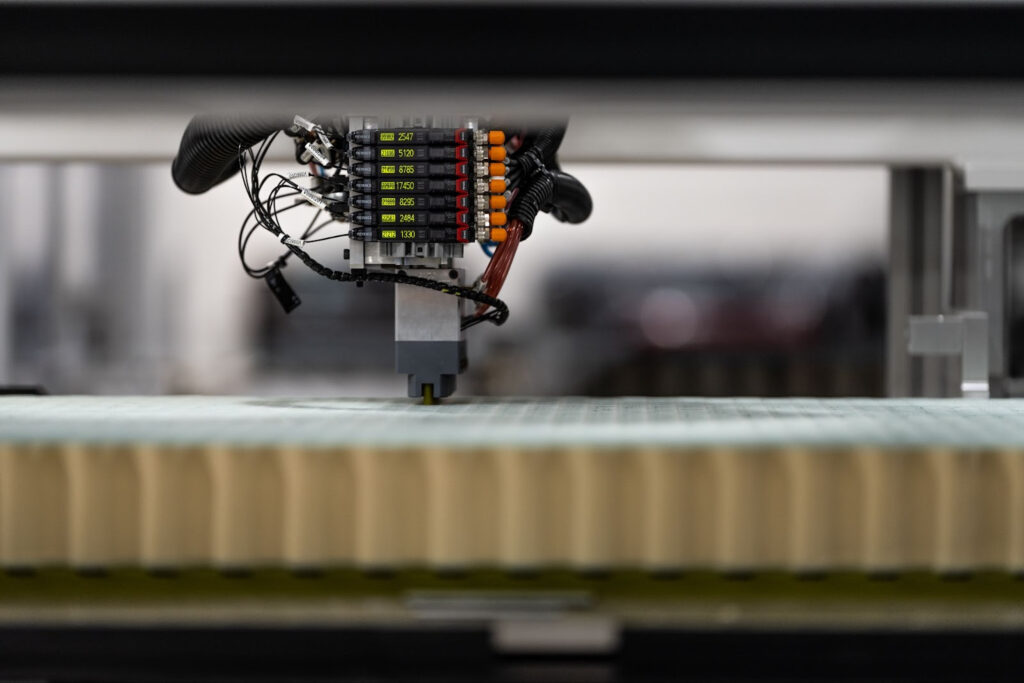

According to Archer, the battery pack manufacturing line was built to be an “automotive style” line that is designed for high-volume production from day one. The final phase of the facility is designed to be capable of producing up to 15,000 battery packs per year. To improve quality, operator safety, and data traceability, Archer has applied automation in key areas of the battery pack manufacturing process, including cell test and load, adhesive dispensing, laser cleaning, laser welding, and end of line testing.

“This is a major milestone for Archer as designing, developing, and mass producing electric propulsion systems that are purpose-built for electric aircraft is the key to unlocking the electrification of aviation,” said Archer CTO Tom Muniz, in the release. “The facility will give us the capability to scale our battery pack production to meet the demands of the output that our Covington, Georgia facility will be capable of.”

Cylindrical cells are loaded into Archer’s proprietary battery pack via an automated manufacturing process. (Photo: Business Wire)

Archer said it chose to vertically integrate its design and manufacturing of the battery pack to ensure it meets the rigorous levels of safety, performance, and reliability necessary for its aviation use case. Archer’s battery pack implements what the company called a “proprietary and robust thermal runaway containment strategy.” The battery packs use cylindrical cells because, relative to other cell form factors, they are said to have a track record of safety, performance, and scalability.

Archer’s battery pack recently successfully completed multiple drop tests, which, the company said, are some of the most challenging tests Archer will face as part of the FAA’s Type Certification program. The tests are said to have further validated the safety and durability of the pack’s proprietary design.

Archer Aviation’s goal is to transform urban travel, replacing 60–90-minute commutes by car with estimated 10-20 minute electric air taxi flights that are safe, sustainable, low noise, and cost-competitive with ground transportation. The company has designed a piloted, four-passenger aircraft, called Midnight, to perform rapid back-to-back flights with minimal charge time between flights.