NIST experts helped identify materials of the F-1 rocket engine that was used in the Apollo program—and had been resting on the Atlantic Ocean floor ever since. (Image copyright: National Air and Space Museum. Transferred from NASA)

Image Source:

https://airandspace.si.edu/collection-objects/rocket-engine-liquid-fuel-f-1/nasm_A19700271000

Like many people, I had dreams of flying into space as an astronaut when I was a child. That interest in aerospace and space exploration has continued throughout my life.

So, when my colleague Tim Foecke, who was working at NIST at the time, invited me to assist with a research project involving the Apollo space program, I jumped at the chance. Tim has a long history in marine forensics and conservation.

Ten massive Saturn V rockets launched astronauts into space during the Apollo missions to the Moon. To reach the Moon, individual rocket pieces, known as stages, were discarded as they ran out of fuel. The first stages of the Saturn V rocket fell into the Atlantic Ocean and have been there since the 1960s and 1970s.

A decade ago, Bezos Expeditions recovered some of these artifacts from the ocean floor. Conservators worked for years to preserve these objects for study.

Many of these pieces are now on display in museums for the public to view and remember the Apollo program. Some of the most intact items were the massive F-1 engines. The conservators determined the artifacts came from Apollo 11, Apollo 13, Apollo 14, and Apollo 16 missions, based on where they were found and serial numbers still visible on some parts.

Tim and I initially worked with some of the conservators to help identify some of the materials used in the rocket engines. However, the conservators had significant challenges with one type of piece—the turbine blades. They found many blades were much lighter than they should be and were fragile to touch.

After being retrieved from its longtime resting place on the Atlantic Ocean floor, a turbine blade from the Saturn V’s rocket engine recently made its way to our lab in Gaithersburg, Maryland, for analysis.

I was initially quite puzzled by the mention of turbine blades. I knew they are commonly used in jet engines, but I initially struggled to figure out how they fit into rocket engines. Reading up on it more, I was astounded to find the turbines were part of a jet engine attached to each rocket, with the sole purpose of driving the fuel and oxygen into the rocket engine!

The Story of the Saturn V Rocket and F-1 Engines

The design for the F-1 rocket engine used in the Saturn V started in the 1950s. The designers imagined the largest capacity engine that might be used in the next decade.

Rocket thrust is the force that determines if the rocket moves at all, what cargo or instruments the rocket can launch, and how quickly the rocket will accelerate as it moves through the air. The designers settled on the round number of 1 million pounds of thrust (4.4 meganewtons) for this engine.

At the time, most rocket engines produced about 120,000 pounds of thrust (530 kilonewtons). So, creating an engine with 10 times that amount of thrust might have seemed a bit absurd. But with the creation of NASA in 1958 and the subsequent space race throughout the 1960s, the idea wasn’t so far-fetched anymore. NASA realized the need for high-thrust engines capable of propelling astronauts all the way to the Moon and back.

By the time the Saturn V designs were finalized, the F-1 engines had been upgraded to 1.5 million pounds of thrust (6.6 meganewtons). The Saturn V used five of these engines for a combined thrust of 7.5 million pounds (33 meganewtons).

All that thrust was needed, as the Saturn V itself was taller than the Statue of Liberty and weighed over 6 million pounds (2.7 million kilograms). The vast majority of the weight was a combination of kerosene, liquid hydrogen, and liquid oxygen to feed the engines. The structure was largely a lightweight hollow tube to hold everything together.

Studying the F-1 Engine Turbine Blade

Each intact turbine blade is about the size of a soda can and looks like a twisted wing of a plane. The shape isn’t too surprising since it has a similar job to an airplane wing. In the case of a turbine, instead of generating lift like a plane wing, the blades create rotation to move fuel and oxygen where it needs to be.

We were initially sent one intact blade, but our studies were limited to observation and testing that wouldn’t damage the sample. Our preliminary analysis indicated it was likely a metallic alloy that can be used at high temperatures, known as a nickel-based superalloy. But this conclusion didn’t match any widely known alloys at the time.

Additionally, since we could only examine the surface of the blade, we weren’t sure the surface measurements were the same as inside the blade.

After discussion of our findings, the conservators gave us four blade fragments that we could cut open and analyze what they looked like inside. It was apparent just by handling the fragments that they were not the solid metal they used to be; they were much too light. We placed the part in a vacuum chamber to support the internal structure and poured an epoxy mix over it. Then, we allowed air into the vacuum chamber, which pushed epoxy into many of the open spaces inside the blade.

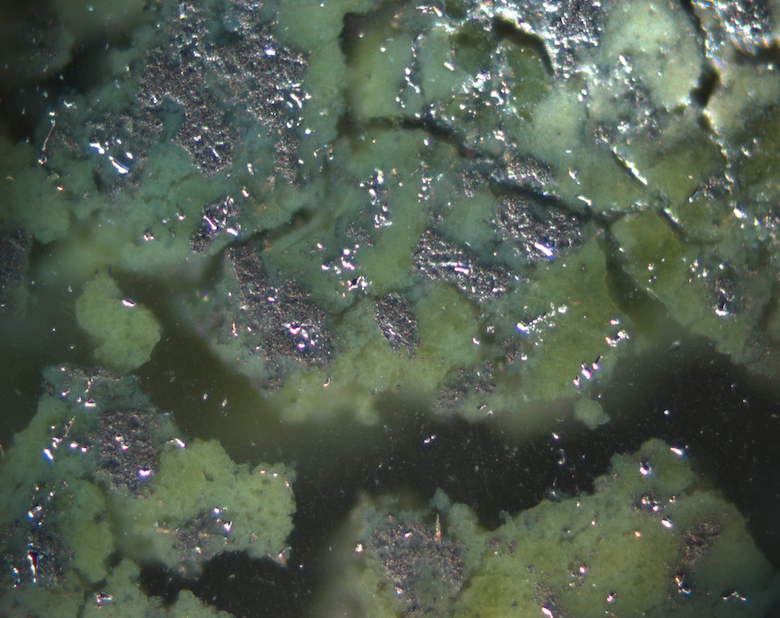

When we looked inside, it was shocking how porous the blades were because the inside had corroded away. The outer surfaces were mostly intact, but the inside was now filled with epoxy, where metal used to be 40-plus years ago. The transparent epoxy supported the fragile metal pores while holding the green corroded metal remnants in place, like the clear ice on a pond that I saw in many winters in the Midwest.

We then used a specialized microscope and other advanced equipment to simultaneously see what was being corroded and how the various elements were distributed throughout the blade. This allowed us to confirm that it was likely an alloy developed specifically for this mission.

As researchers, we didn’t have any background information on what materials were used in the engine. I imagine the company that built the engine decades ago only had to meet NASA’s requirements, and they may not have had to disclose exactly what materials were in it. It’s also possible those records have just been lost over the years.

One of the other mysteries in this project was that in the four turbine assemblies that were found, two of the turbine assemblies were found with their protective covering attached. The other two were found without the cover.

Contrary to expectations, the turbine blades with the protective covering intact were more badly corroded. Reading through other literature on corrosion, I learned this can often occur, where a stagnant environment inside the covering can cause more corrosion than material just exposed to the elements.

An up-close look at a piece of the F-1 engine analyzed at NIST. Transparent epoxy supported the fragile metal holes in the material, while holding the green, corroded metal remnants in place during analysis. (Image courtesy A. Creuziger/NIST)

What Our Research Means for Conservation

The research provided some additional context in a few areas, including:

* what materials were used in the Saturn V engines,

* what was causing the corrosion (and how to prevent it),

* which materials or environments might be more susceptible to this type of corrosion for

future conservators, and

* ideas on how to support fragile samples like this in other applications.

Also unique is that these engines were immersed in an environment (sitting for decades on the ocean floor) quite different from the one they were intended for (spinning rapidly in a flow of hot gas in a rocket engine).

There haven’t been a lot of conservation opportunities for things created so recently, so the results of this work were published as a paper in Studies in Conservation.

Another area where we’re hoping to make an impact is by applying conservation ideas to the data and metadata from our work, as well as the artifacts themselves. In addition to writing the paper, we’ve also prepared a data publication that includes additional images, data, methods, and information about our work for future researchers to build upon the work. This project allowed me to use my knowledge and build upon the significant work the NIST staff has done to make data publicly available over the past decade. We hope the publication helps demonstrate some of what we’ve learned to a broader community.

The conservation of Apollo rocket parts may not seem to overlap much with my primary area of research, which includes developing new tests and standards to incorporate advanced, lighter-weight materials into vehicles for energy and fuel efficiency. But one of the things I love about NIST is that we often get asked to do some fascinating and unusual things. Working at NIST has encouraged me to help people with their technical problems. I get a lot of gratification from solving the problem and then being able to share what we learn freely with the research community and the public.

It was quite an exciting opportunity for me as an aerospace engineer to be a small part of the history of the Apollo space exploration program. It was also neat to go with my family to the Smithsonian Air and Space Museum in Washington, D.C., to see some of the objects. During the video loop introducing the artifacts, the narrator thanked “materials scientists” who worked on the restoration. That was gratifying to hear.

I was born too late to be part of the Apollo program when the rockets were being launched, but it’s nice to be able to still contribute to a part of space exploration in my own way.

Author’s note:

Adam Creuziger would like to thank co-authors Claudia Chemello, Paul Mardikian, and Jerrad Alexander for allowing him to fulfill a childhood aspiration of being involved in the space program by supplying the various rocket parts to investigate, and Megan King for editorial assistance in drafting this article. Adam also acknowledges the substantial contributions to this project and paper from Tim Foecke, Ph.D., prior to his retirement from NIST.

About the Author

Adam Creuziger is a materials research engineer in the Materials Science and Engineering Division at NIST. He joined NIST as a National Research Council (NRC) research associate, starting in 2008, and has been a staff member at NIST since 2012. In 2013, Adam was honored as a Presidential Early Career Award for Scientists and Engineers awardee. Before coming to NIST, Adam graduated with a bachelor of aerospace engineering and mechanics degree from the University of Minnesota, and a master of science and Ph.D. in engineering mechanics from the University of Wisconsin-Madison.

This article first appeared on NIST’s blog, Taking Measure: Just a Standard Blog.

Source: