Keystone’s new top-loading 24mm lithium coin cell holder is said to enable minimal footprint for board layouts without restricting battery access in devices. (Image courtesy Keystone Electronics)

The Keystone wire loop THM Test Points can be used on 0.062-inch-thick and 0.093-inch- thick PCBs with a variety of gripping devices. (Image courtesy Keystone Electronics)

Keystone Electronics has also introduced a 24mm lithium coin cell holder for maximizing PCB capacity.

NEW HYDE PARK, N.Y.—Identification of test points in high density PCB packages is key to greater printed circuit board (PCB) production testing and service troubleshooting, according to Keystone Electronics, a manufacturer of interconnect components and electronic hardware.

To ease this task, Keystone Electronics developed a line of through-hole mount test points with a color-keyed insulator base for visibility and quick identification to replace wire-wrap posts and turret terminals, the company said in a release.

The Keystone wire loop THM Test Points can be used on 0.062-inch-thick and 0.093-inch- thick PCBs with a variety of gripping devices, including J-Hooks, EZ-Hooks, grabbers, alligator clips, tips, and probes. Keystone’s THM test points are also designed to keep on-board terminals perpendicular to the PCB so that relative position, during and after wave soldering, is maintained, the company said.

The test points are available in ten colors: red, black, white, orange, yellow, brown, green, blue, grey, and purple for use with the firm’s Miniature, Compact, and Multi-Purpose Test Points.

Miniature types are manufactured from 0.010-inch (0.25) phosphor bronze with silver or matte tin plating. Compact and Multi-Purpose types employ the same materials sized at 0.015-inch (0.38) diameter. Miniature Test Points mount on a single 0.040-inch (1.0) diameter PCB hole, while Compact and Multi-Purpose styles mount on a 0.063-inch (1.6) diameter PCB hole.

Delivery is from stock through the company’s global distribution network and online ordering partners.

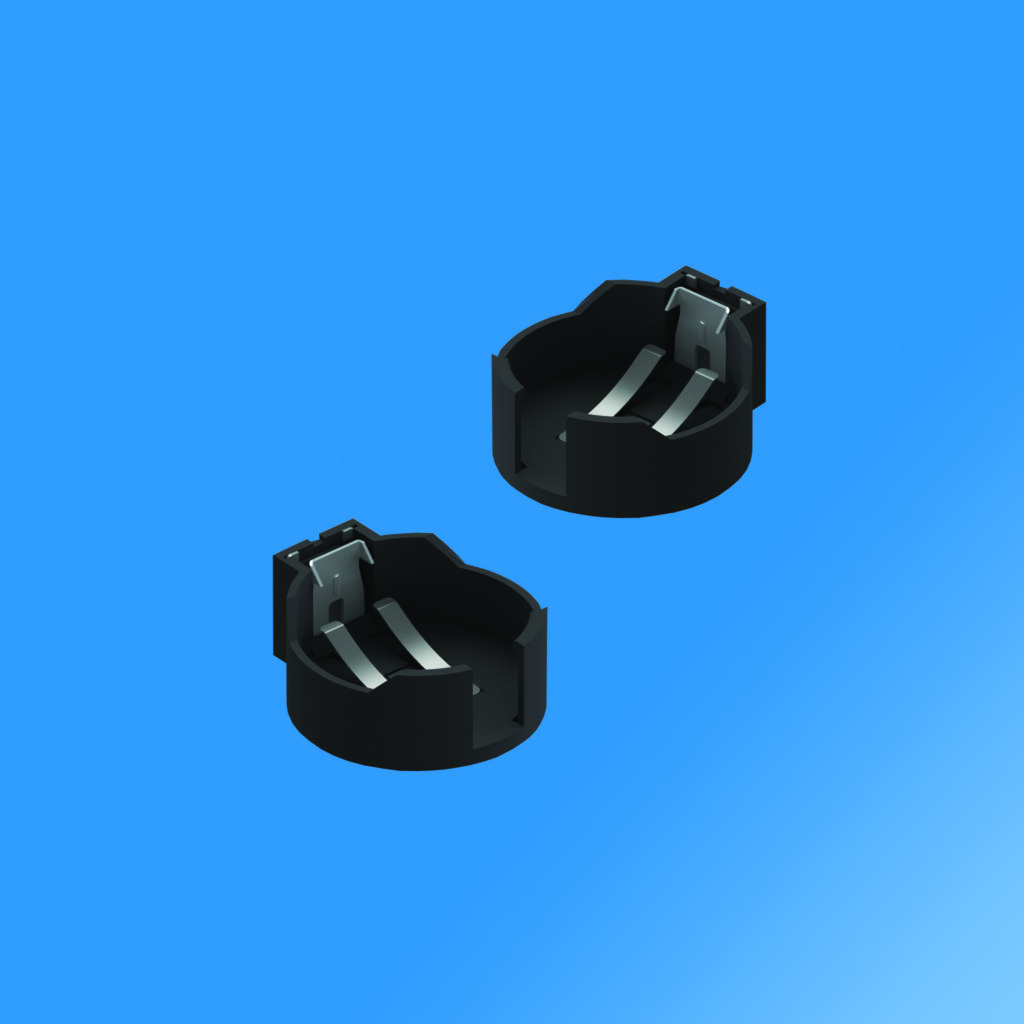

Top-loading lithium coin cell holder reported to save space in high-density applications

Keystone Electronics also reported that it developed a lithium coin cell holder for maximizing PC board capacity when installing high-capacity 2477 lithium coin cells in high-density applications. The coin cell holder’s top-loading design allows for minimal footprint board layouts without restricting battery access in devices, the company said in a release.

The sturdy holder is supplied in a through-hole version and is described as “extremely rugged,” making it suitable for retaining the larger 2477 cells securely in severe shock and vibration environments. Manufactured with nickel-plated phosphor bronze contacts in a PBT, UL rated 94V-0 base, the holder (Keystone Cat. #1009) is reportedly well-suited for circuit back-up power and will accept all major manufacturers’ batteries. It is available from stock through Keystone’s global distribution network and online ordering partners.

Keystone Electronics is a major manufacturer of surface mount technology (SMT) and through-hole mount (THM) battery hardware, in addition to electronic interconnects and hardware. The company offers capabilities in stamping, machining, assembly, CNC, and injection molding services. It also offers application and engineering team assistance for product modifications and special designs.

Keystone is ISO-9001:2015 certified and RoHS compliant, with headquarters in the United States and offices in Canada, Europe, Australia, and Asia.