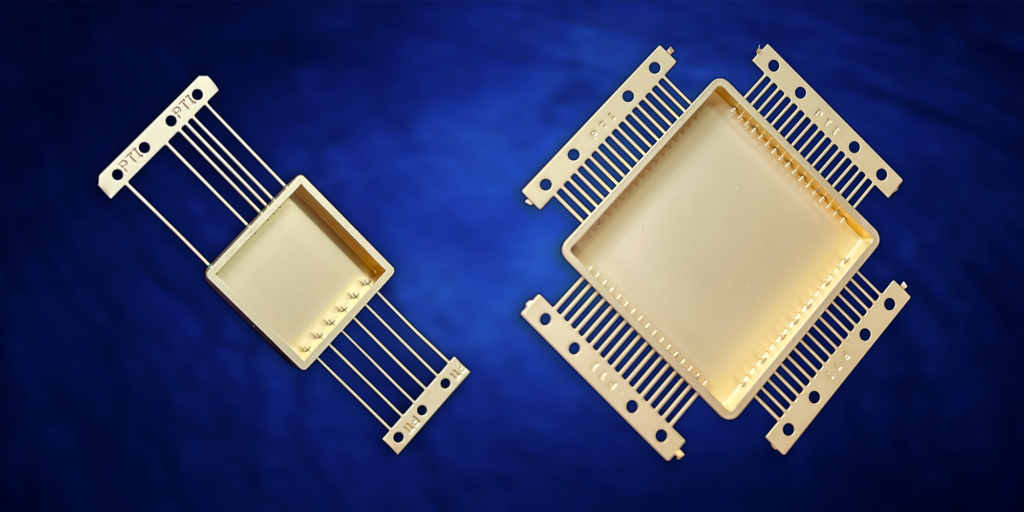

Hybrid packages manufactured by StratEdge. (Image courtesy StratEdge Corp.)

According to semiconductor packages manufacturer StratEdge, no redesigns are required.

SANTEE, Calif.— Hybrid packages carrying integrated microcircuits and components were often developed decades ago and are still vital in many critical defense and aerospace applications today. Today, demand exists for hybrid packages used in legacy applications where redesigns are difficult or impossible, according to a release from StratEdge Corporation.

StratEdge’s capabilities include making hybrid packages that are used in legacy applications. According to StratEdge, ASTM F15 alloy is a key component used to construct hybrid packages, as well as its molded ceramic packages.

“StratEdge has the unique equipment and expertise required to build these types of packages,” said Casey Krawiec, vice president of global sales for StratEdge, in the release. “Our processes for manufacturing molded ceramic packages share many similarities with the requirements for building legacy hybrid packages used in military and space applications.”

The company reportedly excels in glass-to-metal, ceramic-to-metal, and metal-to-metal sealing technologies needed to produce large metal housings with hermetic feedthroughs. Its numerous furnaces have various gas atmospheres required for glass sealing and for brazing or soldering components of various compositions, including metalized ceramic, iron alloys, copper, copper composites, and copper laminates.

StratEdge designs, manufactures, and provides assembly services for high-frequency and high-power semiconductor packages used in radio frequency (RF), microwave, and millimeter-wave devices. The company offers post-fired ceramic and lower-cost molded ceramic packages, specializing in packages for extremely demanding gallium arsenide (GaAs) and gallium nitride (GaN) devices. All packages are lead-free and most meet RoHS and WEEE standards, according to the release.

The company’s markets include telecommunications applications for 5G; very-small-aperture terminals (VSAT); broadband wireless; satellites; defense; test and measurement; automotive; clean energy; and down-hole applications. Its facility in Santee, near San Diego, is both ITAR registered and ISO 9001:2015 certified, the company said.