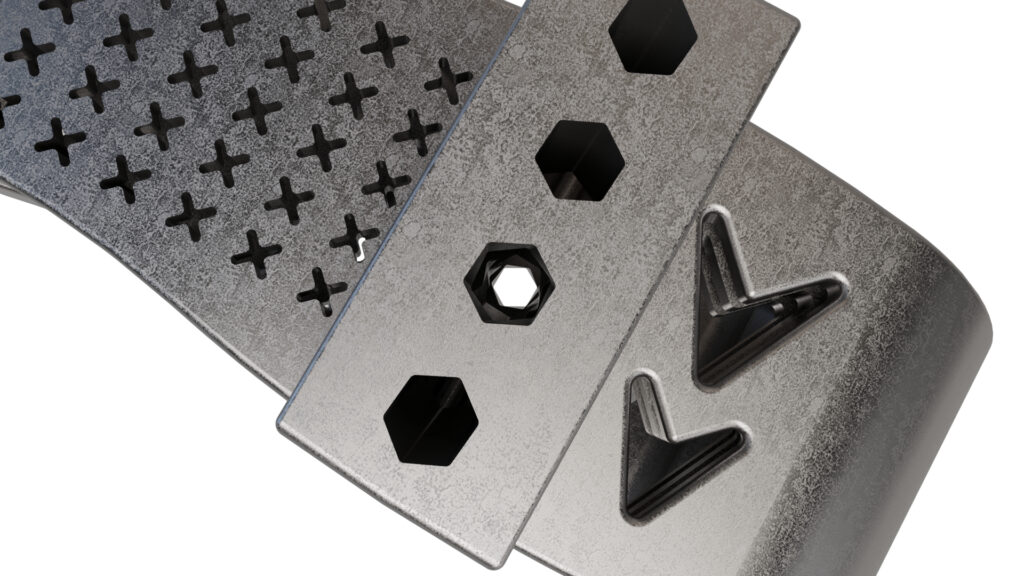

A part designed and produced for metal binder jetting by DSB Technologies. (Photo: Business Wire)

JANESVILLE, Wis.—Powder metal components manufacturer DSB Technologies reported earlier this year that it launched its metal binder jetting prototyping service. The service, available to a diverse customer base, enables customers to leverage the speed and cost efficiency of metal binder jetting to iterate designs more efficiently than conventional metalworking processes, DSB said in a release.

“DSB views this prototyping program as an important stride to educating the marketplace on the capabilities of the metal binder jet technology and helping grow product application opportunities,” said Paul Hauck, chief operating officer for DSB Technologies, in the release. “We are broadening access to DSB’s experienced and knowledgeable 3D printing design and process engineers for customers seeking to prototype and iterate their metal part designs.”

Metal binder jetting, a metal-based additive manufacturing process, is reported to deliver quick print speeds and a high degree of design freedom for metal components with complex geometries. It meets efficient production outputs in a wide range of materials, according to DSB. (See “Driving Metal Binder Jetting into Production,” in Tech Updates)

DSB Technologies said in the release that it is adding the 3D printing prototyping capability to its technology portfolio as a resource for educating the market on the technology’s capabilities. With a customer-provided, print-ready solid model, customers can design and print metal binder jetting prototypes within certain specifications. Prototypes in 17-4 PH stainless steel with a 6-inch cube maximum part size can be printed in two weeks or less. Prototypes in 316L stainless steel, M2 tool steel, and 4140 steel with a 2-inch cube maximum part size can be printed in four weeks or less, according to DSB.

As it adds this prototyping capability to its offerings, DSB Technologies remains committed to industrializing the metal binder jetting process for serial production. The company said that as a metallurgical solutions partner, its offers extensive high-temperature sintering capacity, combined with its parts making expertise, “to drive advancements in the industrialization of metal binder jetting.”

With the prototyping service, customers can benefit from a collaborative partnership that allows them to develop, design, and iterate applications for metal binder jetting more efficiently, the company said.